The Foundations of Furniture-Grade Joinery

As an experienced woodworker, I’ve had the privilege of honing my craft over many years, and one joinery technique that has consistently ranked at the top of my skill priority list is the mortise and tenon joint. This classic union of interlocking wood components is the cornerstone of fine furniture-making, prized for its exceptional strength and durability.

When it comes to woodworking joinery, the mortise and tenon joint is the king of the castle. Its timeless design and unparalleled structural integrity have made it the go-to choice for generations of skilled craftsmen. As I’ve refined my techniques over the decades, I’ve come to deeply appreciate the nuances and challenges this joint presents – from precisely laying out the mortises to carefully shaping the tenons for a seamless fit.

Mastering the mortise and tenon joint is no easy feat, but the rewards are well worth the effort. Not only does it produce furniture of uncompromising quality, but the process of perfecting this joinery method has instilled in me a profound sense of accomplishment and pride. Every time I see the clean, flush lines of a perfectly executed mortise and tenon, I can’t help but reflect on the countless hours I’ve spent honing my skills, experimenting with different tools and techniques, and troubleshooting the occasional hiccup along the way.

Laying the Groundwork: Mortise and Tenon Basics

But before we dive into the nitty-gritty of mortise and tenon joinery, let’s take a moment to establish a common understanding of the fundamental terms and design principles involved.

The mortise is the recessed opening or cavity cut into one piece of wood, while the tenon is the protruding tongue that fits snugly into the mortise on the mating piece. The ideal ratio for this joint is to size the mortise width at approximately one-third the thickness of the workpiece. This strikes a perfect balance between the strength of the tenon and the stability of the surrounding wood.

It’s also crucial to position the mortise at least 3/8″ from the end of the workpiece to prevent splitting during the shaping and assembly process. As for the depth of the mortise, aim for a depth that’s around 1/2 to 2/3 the width of the workpiece – this ensures a secure, long-lasting connection.

Now that we’ve established the foundational elements, let’s explore the various methods for bringing this joint to life in your woodworking projects.

Mortise and Tenon Techniques: Choosing Your Approach

When it comes to creating mortise and tenon joints, woodworkers have a range of techniques and tools at their disposal. The approach you choose will depend on your workshop setup, budget, and personal preference. Let’s dive into some of the most common methods:

Hand-Chiseled Mortises

If you’re working with a basic set of hand tools, the time-honored technique of hand-chiseling the mortises is a great place to start. This method requires no expensive or specialized equipment, making it an accessible option for beginner and experienced woodworkers alike.

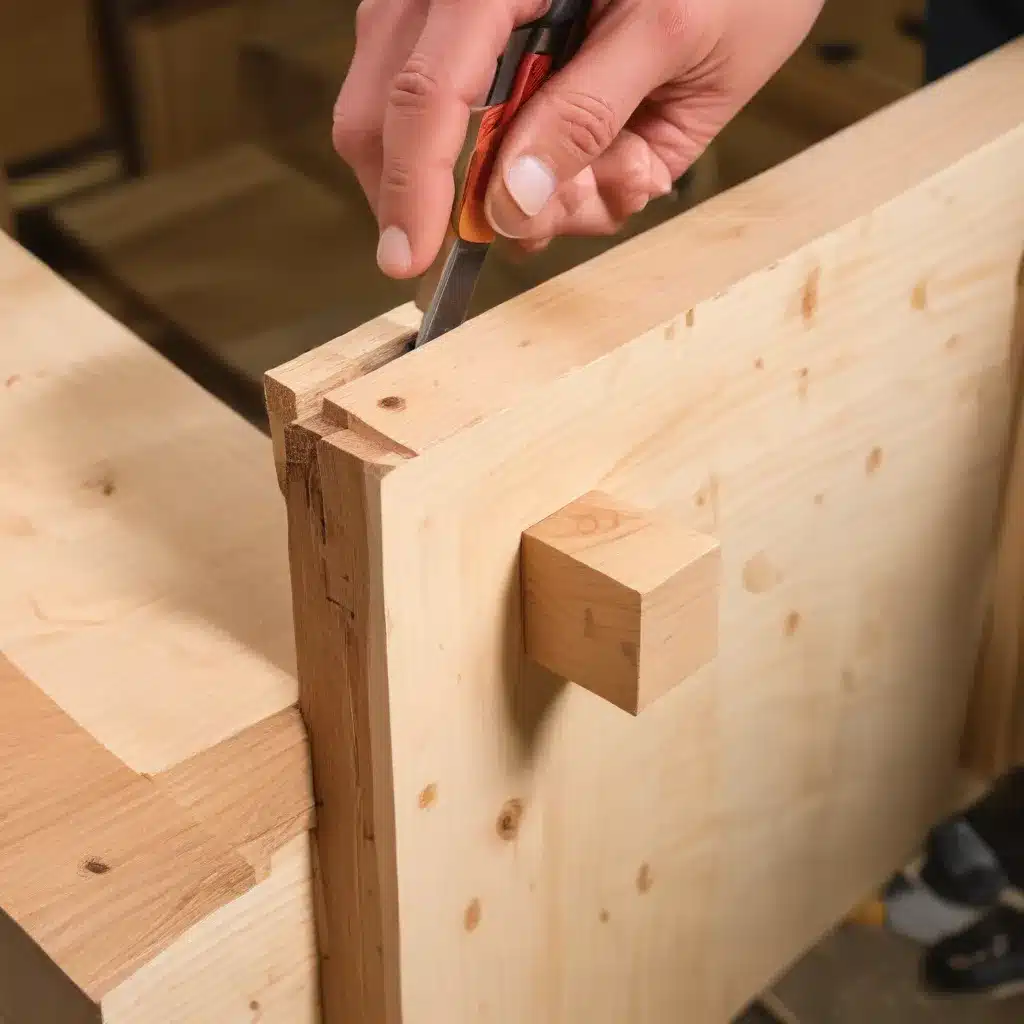

To chisel the mortise, simply mark out the opening with a sharp pencil or knife, then use a series of overlapping drill holes to remove the bulk of the material. Finish the job with a sharp chisel, carefully cleaning up the walls and ensuring a snug, square fit. While this approach does take a bit more time and effort compared to power tool methods, the satisfaction of shaping the mortise by hand is truly unparalleled.

Drill Press Mortising

For those with access to a drill press, the mortising process can be streamlined significantly. Equip your drill press with a brad-point bit that matches the desired mortise width, and use the fence to carefully center the bit between the marked layout lines. By drilling a series of overlapping holes, you can quickly and accurately form the mortise opening, with minimal cleanup required.

The beauty of this method lies in its efficiency and precision. The brad-point bit ensures the holes align perfectly, while the drill press fence helps maintain a consistent, centered mortise every time. It’s a fantastic option for woodworkers who want to minimize the amount of hand-chiseling work.

Mortising Attachments and Machines

If you’re looking to take your mortise-cutting game to the next level, consider investing in a dedicated mortising attachment or machine. These specialized tools use a hollow-chisel design, with a drill bit surrounded by a sharp, square sleeve, to efficiently carve out the mortise in a single pass.

Mortising attachments that clamp onto your existing drill press can be a cost-effective solution, while benchtop mortisers provide a dedicated, always-ready workspace for this task. Both options yield clean, square mortises with minimal effort, making them a valuable asset in high-volume furniture or cabinetmaking shops.

Crafting the Tenon: Matching Your Tools to the Task

With the mortises expertly carved, it’s time to turn our attention to the other half of the equation: the tenons. The key is to create a tenon that slides snugly into its mating mortise, with a hidden gap that allows for excess glue and prevents the joint from bottoming out.

There are several techniques for cutting tenons, each with its own advantages and considerations. Let’s explore a few of the most common methods:

Tablesaw Tenoning

In my workshop, I often turn to the trusty tablesaw for cutting tenons. By aligning the rip fence parallel to the dado set and ensuring a perfectly square miter gauge fence, I can quickly and reliably produce tenons with clean, tight-fitting shoulders.

The beauty of this approach lies in its simplicity and the fact that the workpiece remains fully supported on the table throughout the process. Just be mindful of the potential for lesser-quality dado sets to produce a rougher surface, which may require additional sanding before assembly.

Bandsaw Tenoning

For those who prefer to avoid the complexities of a dado set, the bandsaw can be a fantastic alternative for cutting tenons. By supporting the workpiece vertically and using a resaw-style blade, you can easily shape the tenon cheeks with clean, smooth results.

The main advantage of the bandsaw method is its ability to handle longer workpieces that may be unwieldy on the tablesaw. Just be sure to account for any blade drift and make test cuts to ensure a perfect fit.

Tenoning Jigs and Fixtures

If you’re looking for a jig-based approach to tenon cutting, there are several well-designed options available on the market. These fixtures, whether shop-made or commercially available, allow you to securely clamp the workpiece and guide it through the cut, ensuring a square, consistent tenon every time.

While these jigs may require a bit more setup time, the precision and convenience they offer can be invaluable, especially when working with larger or more complex workpieces. Plus, the ability to fine-tune the tenon dimensions with a dedicated jig can make the difference between a snug, seamless joint and one that requires extensive tweaking.

Perfecting the Fit: Adjusting Tenon Dimensions

Even with the most careful planning and execution, it’s not uncommon to end up with a tenon that’s slightly oversized or undersized. But fear not, skilled woodworkers have a few tricks up their sleeves to ensure a perfect fit.

For a tenon that’s just a hair too thick, I like to use a sanding block with self-adhesive sandpaper to carefully remove material until the joint slides together with firm hand pressure. Avoid the temptation to use sandpaper directly on the tenon, as this can compromise the clean, straight lines of the shoulders.

Alternatively, a rabbeting plane provides a delicate touch for shaving down an oversize tenon. By taking light, controlled passes, you can gradually reduce the thickness until the joint achieves the desired fit.

On the flip side, if the tenon is a bit too thin, a simple solution is to glue on a filler piece and then plane or sand the tenon to the final, perfect dimensions. This approach allows you to maintain the integrity of the joint while ensuring a seamless, snug connection.

No matter which adjustment method you choose, the key is to take it slow and test the fit frequently. A well-executed mortise and tenon joint is a true work of art, and the journey to perfecting this timeless technique is one that every dedicated woodworker should embrace.

Mastering Compound Angle Joinery

While the standard 90-degree mortise and tenon joint is an essential skill, the true test of a seasoned woodworker often lies in their ability to tackle more complex, compound angle joinery. This specialized technique is particularly crucial for projects like chairs, where the rear legs may cant inward while the front legs remain perpendicular to the floor.

Crafting these intricate joints requires a deep understanding of the underlying geometry and a meticulous approach to layout and execution. The key is to start by breaking down the problem into its component angles – the cant of the leg, seen in the front elevation, and the trapezoidal shape of the seat frame, visible in the plan view.

By carefully drafting the joint details and accurately transferring the layout lines to the workpieces, you can ensure that the mortises and tenons seamlessly align, even with the presence of compound angles. While this process may seem daunting at first, the satisfaction of seeing a beautifully executed compound joint come together is unmatched.

As with any advanced woodworking technique, the path to mastering compound angle joinery is paved with practice, patience, and a keen eye for detail. But by embracing the challenge and methodically honing your skills, you’ll unlock a new level of craftsmanship that will elevate your furniture projects to new heights.

Maintaining Woodworking Tools for Precision and Efficiency

Of course, no discussion of mortise and tenon joinery would be complete without addressing the critical role of well-maintained tools. As an experienced woodworker, I’ve learned that the key to consistently producing high-quality joints lies not just in mastering the techniques, but also in ensuring that my tools are in peak condition.

Whether it’s keeping my chisels razor-sharp, meticulously tuning my tablesaw, or carefully tensioning my bandsaw blade, I’m constantly vigilant about the state of my equipment. After all, a dull blade or a misaligned fence can quickly compromise the precision and accuracy that are so essential to this type of joinery.

By investing time in regular tool maintenance and sharpening, I’m able to work with confidence, knowing that my tools will perform at their very best. And when the occasional issue does arise, such as the slight shift in my sash factory’s fence that Scott and I encountered, I’m equipped with the knowledge and problem-solving skills to quickly diagnose and remedy the problem.

Ultimately, the mastery of mortise and tenon joinery is a lifelong journey, one that requires a steadfast commitment to continuous learning, experimentation, and a deep appreciation for the craft. But for those of us who have been bitten by the woodworking bug, there’s simply no greater satisfaction than seeing the results of our hard-earned skills – a beautifully constructed piece of furniture that will stand the test of time.

If you’re ready to embark on your own mortise and tenon joinery adventure, I encourage you to explore the wealth of resources available on our website. From in-depth tutorials to expert product recommendations, we’re here to support you every step of the way. Happy woodworking!