Mastering the Art of Precise Woodworking Measurements

As an experienced woodworker and craftsman, I’ve learned that precision in measurements is the foundation for creating exceptional woodworking projects. Whether you’re building a rustic farmhouse table, crafting intricate furniture pieces, or tackling custom cabinetry, the ability to accurately measure, mark, and cut your wood is crucial. In this comprehensive guide, I’ll share the secrets, techniques, and insights I’ve gathered over the years to help you unlock the power of precise woodworking measurements and elevate your projects to new heights.

Understanding Wood Characteristics and Their Impact on Measurements

Before we dive into the specifics of measuring, it’s essential to understand the unique properties of wood and how they can affect your project measurements. Different wood species have varying densities, grains, and moisture content, all of which can influence the way the material behaves and the accuracy of your measurements.

For example, softwoods like pine tend to be more prone to expansion and contraction due to changes in humidity, while hardwoods like oak are generally more stable. Knowing the specific characteristics of the wood you’re working with can help you anticipate potential challenges and adjust your measurement techniques accordingly.

Mastering the Fundamentals of Woodworking Measurements

At the core of precise woodworking measurements are a few key tools and techniques that every craftsman should have in their arsenal. Let’s explore these essentials:

Choosing the Right Measuring Tools

The success of your woodworking projects often hinges on the quality and accuracy of your measuring tools. Invest in high-quality rulers, tape measures, calipers, and squares to ensure you’re getting the most precise readings. Avoid cheap, flimsy tools that can easily become misaligned or damaged.

Proper Measuring Techniques

Proper measuring technique is just as important as the tools themselves. Always measure from the same consistent reference point, such as the edge of the wood or a marked line. Take multiple measurements to cross-check your work and ensure consistency. When measuring longer pieces, use a straight edge or a solid surface as a guide to maintain accuracy.

Understanding Measurement Conversions

Woodworkers often work with a variety of measurement units, including inches, fractions, and metric. Familiarize yourself with the process of converting between these units to avoid costly mistakes. Keep a conversion chart handy or use a digital calculator to quickly translate measurements as needed.

Marking and Transferring Measurements

Accurately marking and transferring your measurements to the wood is crucial. Use a sharp pencil or a fine-tipped marker to make clear, precise marks. When transferring measurements from one piece to another, take the time to double-check your work and ensure the markings align correctly.

Strategies for Precise Woodworking Cuts

Once you’ve mastered the fundamentals of woodworking measurements, the next step is to apply those skills to the cutting process. Here are some strategies to help you achieve clean, accurate cuts every time:

Proper Saw Blade Alignment

Ensure that your saw blades are properly aligned and maintained. A dull or misaligned blade can lead to inaccurate cuts and uneven edges. Take the time to regularly sharpen and adjust your saws to maintain peak performance.

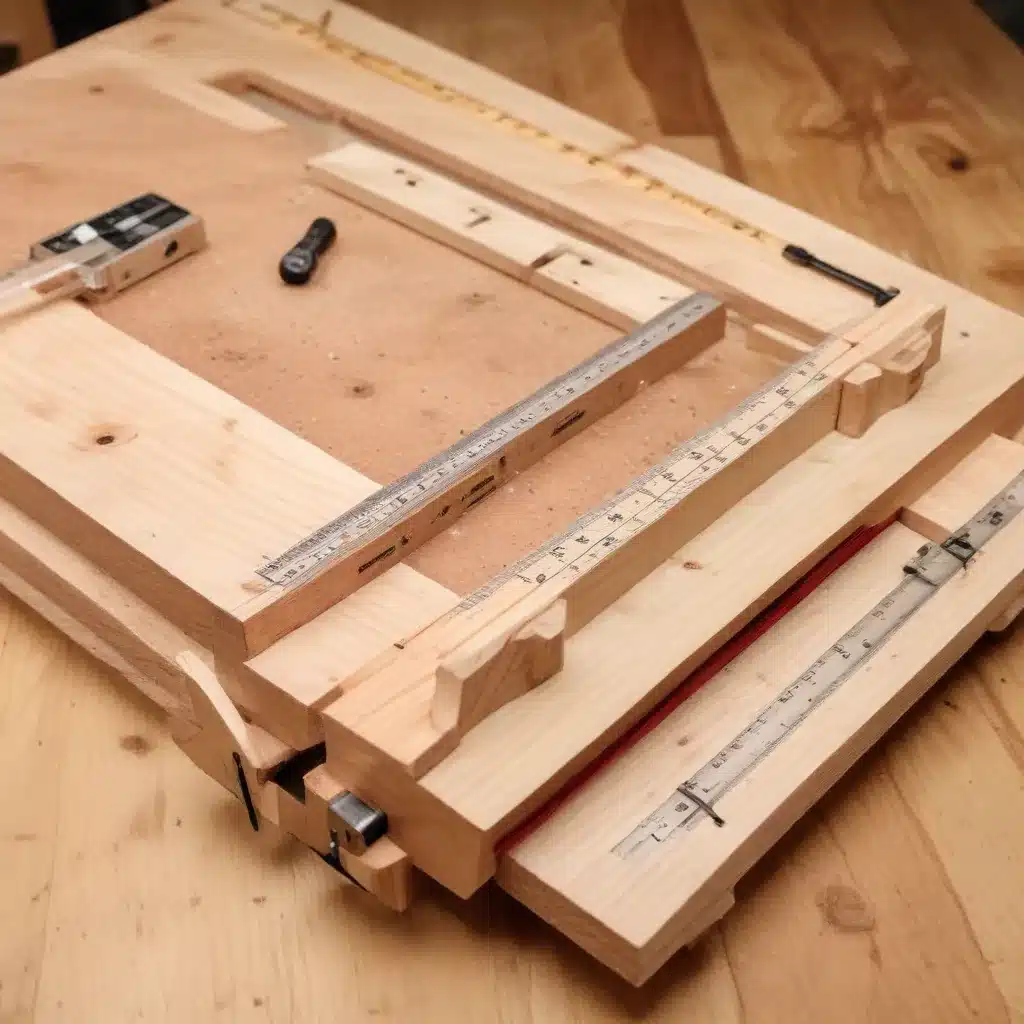

Utilizing Jigs and Guides

Invest in high-quality jigs and guides, such as miter saws, table saw fences, and router templates, to ensure your cuts are precisely aligned with your measurements. These tools can help you achieve consistent, repeatable results and reduce the risk of costly mistakes.

Careful Layout and Marking

Before making a cut, take the time to carefully lay out and mark your measurements on the wood. Use a square or a straight edge to ensure your marks are perfectly perpendicular or parallel to the edges. Double-check your work to avoid any errors.

Slow and Steady Cutting Technique

When making the actual cut, maintain a steady, controlled pace. Rushing through the process can lead to uneven or jagged edges. Take your time, keep the saw blade aligned with your markings, and let the tool do the work.

Combating Wood Movement and Seasonal Changes

One of the biggest challenges in woodworking is dealing with the natural movement and expansion of wood due to changes in humidity and temperature. This can have a significant impact on your measurements and the overall success of your projects.

To address this issue, consider the following strategies:

Monitoring Moisture Content

Regularly monitor the moisture content of your wood using a moisture meter. This will help you anticipate and account for any potential changes in the material’s dimensions as the humidity fluctuates.

Acclimating Wood to Your Workshop

Before beginning a project, allow your wood to acclimate to the humidity and temperature of your workshop. This can help minimize the impact of wood movement and ensure a more stable, consistent final product.

Incorporating Allowances for Wood Movement

When planning your projects, incorporate strategic allowances for wood movement. This might involve leaving a bit of extra space between panels or using joinery techniques that can accommodate slight changes in the wood’s dimensions.

Leveraging Technology for Precision Woodworking

In today’s digital age, there are a wealth of technological tools and resources available to help woodworkers achieve unparalleled precision. Embrace these advancements to take your measurements and project planning to the next level:

Computer-Aided Design (CAD) Software

Utilize CAD software to create detailed, scale drawings of your projects. These digital models can help you visualize the final product, identify potential issues, and refine your measurements before ever picking up a tool.

Digital Measuring Devices

Explore the use of digital calipers, micrometers, and laser distance meters to take highly accurate measurements with reduced risk of human error. These advanced tools can provide precise readings and seamlessly integrate with your project planning software.

3D Scanning and Modeling

For complex or custom projects, consider using 3D scanning and modeling technologies to capture precise dimensional data. This can be especially valuable when working with intricate pieces or irregular shapes.

Maintaining and Calibrating Your Woodworking Tools

To ensure the accuracy and consistency of your measurements, it’s crucial to properly maintain and calibrate your woodworking tools. This includes:

Regular Cleaning and Sharpening

Keep your saws, chisels, planes, and other tools clean and sharp. Dull or damaged tools can lead to inaccurate cuts and measurements.

Calibrating Measuring Tools

Periodically check the calibration of your rulers, squares, and other measuring devices to ensure they are providing reliable, consistent readings.

Proper Tool Storage and Handling

Protect your tools from damage by storing them properly and handling them with care. Dings, dents, and other physical impacts can throw off your measurements.

Incorporating Eco-Friendly Practices

As a responsible woodworker, it’s important to consider the environmental impact of your craft. Embrace eco-friendly practices that can help reduce waste and minimize your carbon footprint:

Efficient Material Utilization

Carefully plan your projects to maximize the use of each piece of wood, minimizing offcuts and waste. Utilize scrap materials wherever possible.

Repurposing and Recycling

Look for opportunities to repurpose or recycle used wood and materials, rather than sending them to the landfill.

Sourcing Sustainable Wood Supplies

Prioritize purchasing wood from sustainable, responsibly managed sources to support the long-term health of our forests.

Applying Your Woodworking Measurement Expertise

Now that you’ve mastered the art of precise woodworking measurements, it’s time to put your newfound knowledge into practice. Whether you’re tackling a custom furniture piece, building a stunning garden arbor, or creating intricate wood carvings, these principles and techniques will serve as the foundation for your success.

Remember, attention to detail and a commitment to precision are the hallmarks of a true woodworking master. Embrace the challenge, hone your skills, and let your passion for the craft shine through in every project you undertake.

If you’re interested in exploring more woodworking resources and connecting with a community of fellow enthusiasts, be sure to visit https://woodcraftparts.net/. There, you’ll find a wealth of information, tools, and inspiration to help you elevate your woodworking journey.

So, grab your trusty tape measure, sharpen your tools, and get ready to create masterpieces that will stand the test of time. The secrets of precise woodworking measurements are now at your fingertips – go forth and build your dreams!