Harnessing the Power of Jigs

As an experienced woodworker, I’ve learned that the true secret to unlocking the full potential of your projects lies not just in the quality of your tools, but in the ingenious use of woodworking jigs. These unsung heroes of the workshop can transform even the most challenging tasks into streamlined, precision-driven endeavors. In this comprehensive guide, I’ll share my insights on the art of jig-making and how these versatile tools can revolutionize your woodworking experience.

Imagine a world where every cut, every joint, and every detail is consistently executed with unwavering accuracy. That’s the promise of well-designed woodworking jigs. These fixtures serve as extensions of your hands, guiding your tools and workpieces with a level of control that’s simply unattainable through freehand methods. Whether you’re building furniture, crafting intricate woodturnings, or tackling any other woodworking project, the right jigs can be your gateway to consistently remarkable results.

The Jig Advantage

What makes jigs so invaluable in the world of woodworking? It all boils down to their ability to enhance precision, repeatability, and efficiency. By creating a dedicated setup for specific tasks, jigs eliminate the guesswork and variability that can creep in when working without them.

Precision

Jigs are designed to ensure that critical dimensions, angles, and alignments are maintained with pinpoint accuracy. This is particularly important when dealing with complex joinery, intricate profiles, or any project that demands tight tolerances. With a well-crafted jig, you can trust that every mortise, tenon, or dovetail will fit together seamlessly, elevating the overall quality of your work.

Repeatability

One of the most compelling advantages of jigs is their ability to facilitate repeatable results. If you need to create multiple identical parts, a jig allows you to replicate the process with consistent outcomes. This is a game-changer when building furniture, cabinetry, or any other project that requires identical components. No more relying on freehand measurements and hoping for the best – the jig ensures that each piece aligns perfectly with its counterparts.

Efficiency

Jigs don’t just enhance precision and repeatability; they also drastically improve efficiency. By streamlining complex or time-consuming tasks, jigs can save you valuable workshop time. Instead of meticulously measuring and marking each workpiece, you can simply clamp it into the jig and let the tool do the work. This not only speeds up the process but also reduces the risk of errors, allowing you to focus your energy on the creative aspects of your project.

Jig Design and Fabrication

The true power of jigs lies in their versatility and customizability. As a seasoned woodworker, I’ve found that the most effective jigs are often the ones you design and build yourself, tailored to the specific needs of your project and your workshop. Let’s dive into the process of conceiving and creating these invaluable tools.

Identifying Needs

The first step in jig-making is to identify the tasks or challenges you’re facing in your current projects. What processes require greater precision or repeatability? Where do you find yourself struggling with efficiency or accuracy? These pain points are the foundation upon which you’ll build your jig solutions.

Sketching and Planning

Once you’ve identified the areas that could benefit from a jig, it’s time to start sketching and planning. Visualize the ideal setup, considering the materials, dimensions, and features that will enable the jig to perform its intended function. Don’t be afraid to experiment with different designs, as the most innovative jigs often emerge from an iterative process of trial and error.

Material Selection

The choice of materials for your jig is a critical consideration. Depending on the application, you may opt for sturdy hardwoods, precision-milled aluminum extrusions, or a combination of various materials. The key is to select substances that will provide the necessary rigidity, stability, and durability to withstand the demands of your woodworking projects.

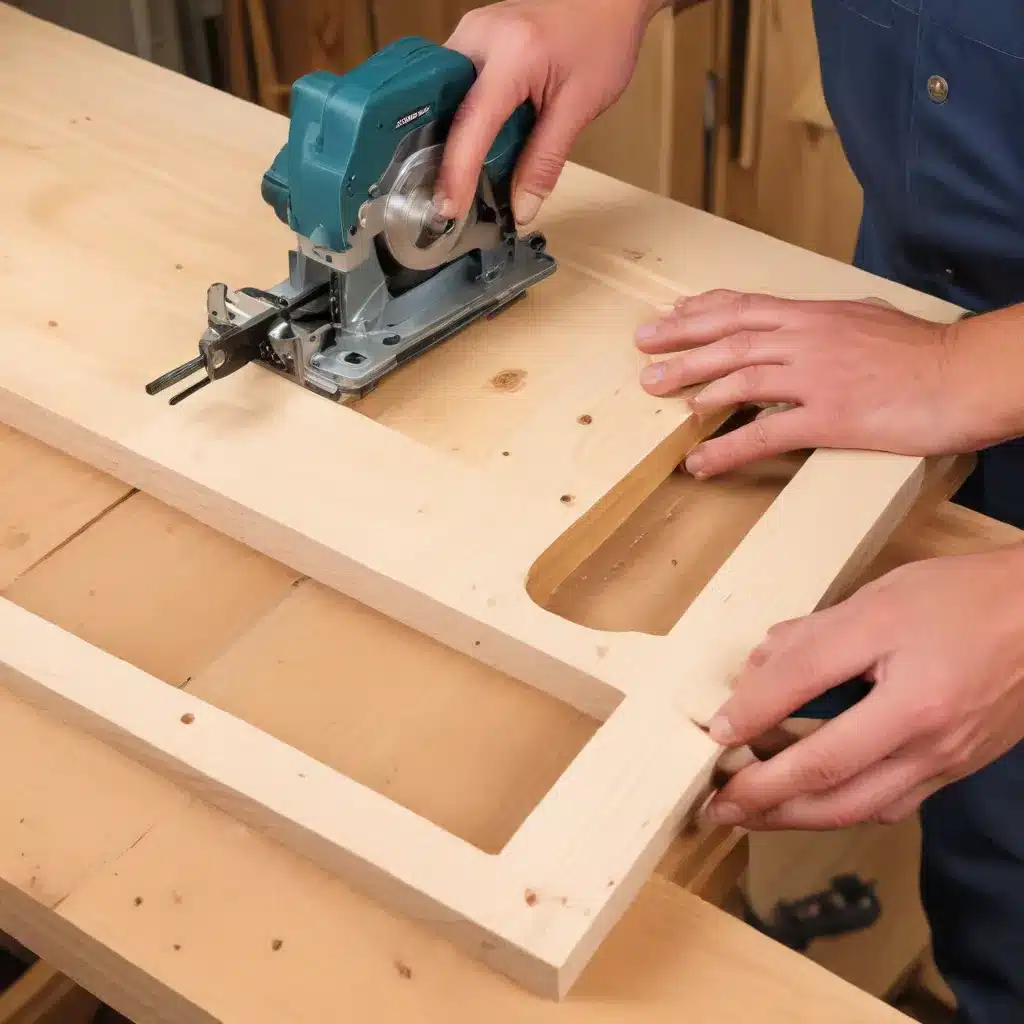

Fabrication Techniques

With your design finalized and materials on hand, it’s time to begin the fabrication process. This can involve a range of techniques, from simple hand tools to more advanced power tools and machines. Depending on the complexity of your jig, you may need to employ methods like cutting, shaping, drilling, and joinery to bring your creation to life.

Prototyping and Testing

Before committing to a final jig design, it’s wise to create a prototype and put it through its paces. Test the jig with your actual woodworking tasks, making any necessary adjustments to ensure optimal performance. This iterative process is essential for refining the design and ensuring the jig delivers the desired results.

Jig Applications Across Woodworking Disciplines

Woodworking jigs can be tailored to a wide range of applications, from furniture-making to woodturning and beyond. Let’s explore a few examples of how these versatile tools can enhance various aspects of your craft.

Furniture and Cabinetry

In the realm of furniture and cabinetry, jigs are indispensable for achieving precision joinery. From dovetail jigs that simplify the creation of intricate joints to router table fences that ensure perfectly aligned edges, these tools are essential for producing high-quality, heirloom-worthy pieces.

One of my favorite jigs for furniture-making is a dedicated mortise and tenon jig. By providing a consistent and repeatable setup for milling these critical joints, I can streamline the process and ensure a perfect fit every time. This not only saves me time but also elevates the structural integrity of my projects.

Woodturning

Woodturning is another discipline where jigs can dramatically enhance both the creative process and the final outcome. Whether you’re crafting bowls, pens, or decorative spindles, the right jigs can help you achieve remarkable precision and consistency.

For example, a dedicated pen-turning jig can simplify the process of drilling accurate holes for the pen mechanism, while a steady rest jig can provide invaluable support when turning long, slender workpieces. These specialized tools allow me to focus on the artistry of my work, rather than worrying about the technical aspects.

Specialty Woodworking

Beyond furniture and turning, woodworking jigs can be applied to a vast array of specialty projects, from intricate marquetry to custom-built musical instruments. In these niche disciplines, the need for precision is paramount, and jigs become essential tools for achieving the desired results.

One specialty application that comes to mind is the creation of custom box joints for box-making. By using a dedicated jig, I can cut perfectly matched fingers and ensure a seamless, interlocking fit, elevating the overall quality and visual appeal of my boxes.

Maintaining and Optimizing Your Jigs

As with any valuable tool in your workshop, proper maintenance and optimization of your jigs are crucial to ensuring their long-term performance and effectiveness. Here are some tips to keep your jigs in top shape:

Cleaning and Lubrication

Regularly cleaning your jigs and keeping their moving parts well-lubricated can extend their lifespan and maintain their precision. Use a soft cloth and gentle cleaners to remove any accumulated dust or debris, and apply a light coat of oil or wax to sliding surfaces and pivot points.

Calibration and Adjustments

Over time, even the most meticulously crafted jigs can experience slight shifts or misalignments. Periodically check the critical dimensions and settings of your jigs, making any necessary adjustments to ensure they continue to deliver the level of precision you expect.

Upgrades and Modifications

As your woodworking skills and project needs evolve, don’t be afraid to upgrade or modify your existing jigs. Perhaps you’ve discovered a more efficient way to clamp a workpiece or identified an opportunity to enhance the functionality of a particular jig. By staying open to improvements, you can continually optimize your jigs to keep pace with your growing expertise.

Embracing the Jig Mindset

Ultimately, the true power of woodworking jigs lies not just in their practical applications, but in the mindset shift they can inspire. By embracing the jig-centric approach, you’ll find that your entire woodworking experience becomes more streamlined, more consistent, and more enjoyable.

As you embark on your next project, I encourage you to start thinking about how jigs can help you unlock new levels of precision and efficiency. Experiment with different designs, continuously refine your techniques, and don’t be afraid to invest time in creating custom solutions tailored to your unique needs.

Remember, the road to woodworking mastery is paved with the strategic use of jigs. By leveraging these versatile tools, you’ll not only produce exceptional results but also free up mental bandwidth to focus on the creative aspects of your craft – the very essence of what makes woodworking such a rewarding and fulfilling pursuit.

So, let’s dive in and uncover the transformative power of woodworking jigs together. Whether you’re a seasoned pro or a passionate hobbyist, the insights and techniques I’ve shared in this article will empower you to elevate your projects to new heights of excellence. Onward to a world of precision, efficiency, and the pure joy of crafting with wood!

Conclusion

Woodworking jigs are the unsung heroes of the workshop, quietly transforming the way we approach our craft. By harnessing the power of these versatile tools, we can unlock new levels of precision, repeatability, and efficiency in our projects. From furniture and cabinetry to woodturning and specialty applications, jigs can be tailored to meet the unique demands of any woodworking discipline.

In this comprehensive guide, I’ve shared my insights and experiences as an experienced woodworker, highlighting the myriad benefits of incorporating jigs into your workflow. By identifying your needs, designing and fabricating custom solutions, and maintaining your jigs to peak performance, you’ll be well on your way to elevating the quality and consistency of your work.

Remember, the true value of jigs extends far beyond their practical applications. By embracing the jig-centric mindset, you’ll find that your entire woodworking journey becomes more streamlined, more rewarding, and more fulfilling. So, let’s embark on this exciting exploration together and unlock the full potential of your woodworking projects.

Discover the world of woodworking jigs at https://woodcraftparts.net/, where you’ll find a wealth of resources, tools, and inspiration to help you on your journey. Happy crafting!