The Importance of Sharp Turning Tools

As an experienced woodworker and craftsman, I can’t stress enough the significance of maintaining razor-sharp tools for your lathe. The correlation between well-tuned tools and turning success cannot be overstated. Dull tools can lead to a frustrating and subpar woodworking experience, while a sharp, well-honed edge can make all the difference in your projects.

When it comes to turning, the dulling effect of cutting can happen surprisingly quickly. Even after just a minute or two of use, you may notice a distinct change in the tool’s performance. A dull tool will resist taking light cuts, requiring extra pressure and increasing vibration, which can limit the range and fluidity of your motions. This is a recipe for a less-than-ideal turning session.

Imagine a 2-inch diameter round spinning at 800 rpm – after just 30 seconds of cutting, over 210 linear feet of wood have passed against the edge! This underscores the importance of maintaining your tools and staying on top of regular sharpening.

Choosing the Right Turning Tools

While it’s tempting to think that having more tools equates to greater ability, the reality is that knowing when and how to use the right tools is far more important. My basic turning kit contains a few key essentials:

- 3/4″ Roughing Gouge: This does the heavy shaping work.

- 1/8″ Diamond Parting Tool: For sizing diameters.

- 3/4″ Oval Skew: For finishing all surfaces except coves.

- 3/8″ Detail Gouge: For getting into coves and roughing out beads.

These four tools are more than sufficient for most of my turning tasks. By limiting my collection, I can keep all my tools in top condition with ease and know exactly which one to reach for at each step.

Sharpening Techniques for Turning Tools

Proper sharpening is crucial for maintaining your tools and ensuring a consistently smooth and efficient turning experience. Here are the techniques I use for sharpening my key turning tools:

Roughing Gouge

I use a 35-degree bevel on my roughing gouge, and it’s important that the profile is straight. This keeps the cuts fluid and predictable. I use a jig to grind the gouge for consistent results, then hone the bevel with small diamond-impregnated paddles. I remove the burr with a diamond hone and occasionally turn the burr from the inside of the flute with a leather strop.

Diamond Parting Tool

For my 1/8″ wide diamond parting tool, I grind at around a 50-degree inclusive angle, focusing on keeping the edge straight across. I don’t hone this tool, as I grind it too often for honing to be practical.

Oval Skew

I sharpen my oval skew at a 30-degree inclusive angle, using a standard tool rest on my grinder. I shape the edge to a subtle curve, which allows for an exceptionally light cut and reduces the likelihood of catches. I hone the tool on stones, being careful to maintain the flat facet behind the cutting edge.

Detail Gouge

Before grinding, I polish the inside flute of the detail gouge to remove any milling marks. I then use a commercial jig to grind it to a consistent fingernail profile at a 35-degree angle. I finish the honing the same as the roughing gouge.

The key for all these tools is maintaining flat bevels and an extremely sharp edge. Any rounding over of the bevel will make the tool difficult to control. Hollow grinds help me achieve this, with the exception of the inside of the gouges, where a slight rounding can be tolerated.

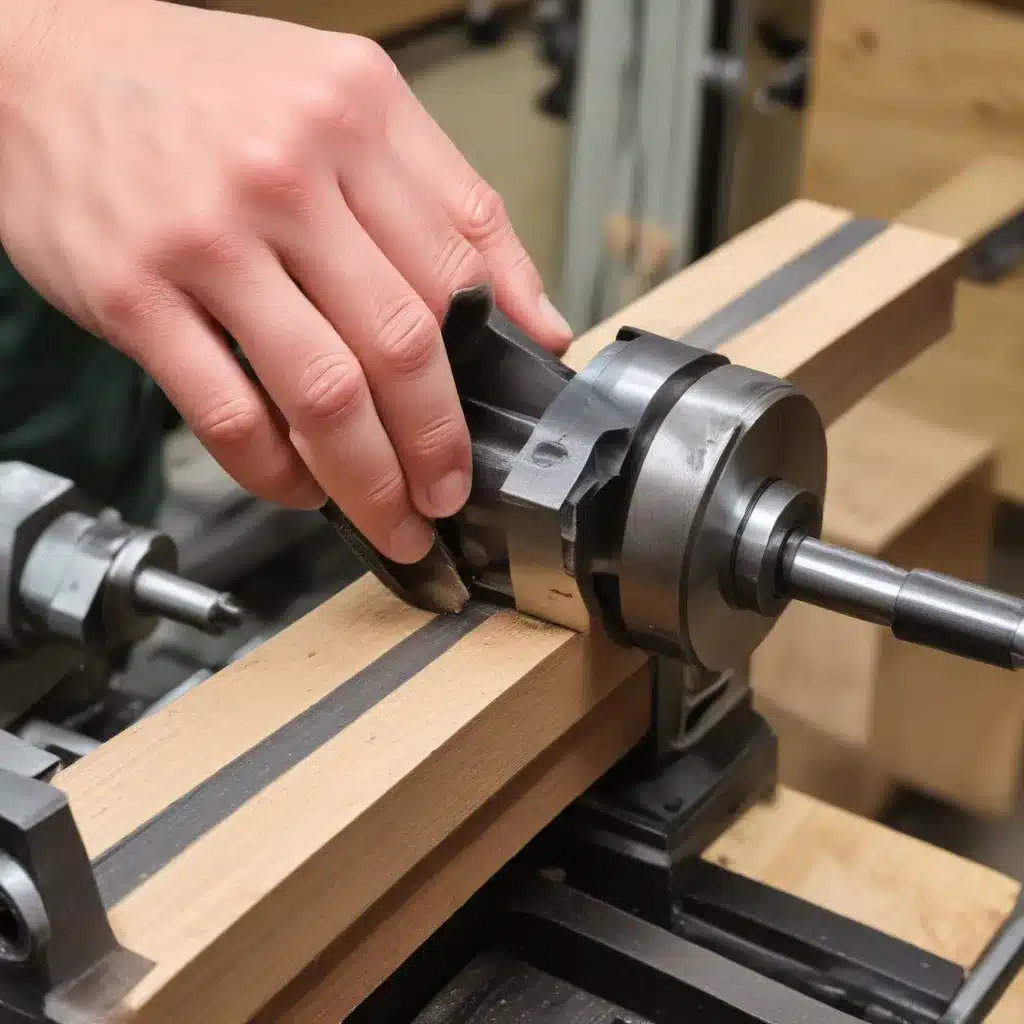

Lathe Tool Maintenance

But sharpening is just one part of the equation. The condition of your lathe’s tool rest is also crucial for smooth turning. A pitted or dinged-up tool rest can make even the sharpest tools perform poorly, so I make sure to keep mine in top shape.

I use a smooth file to level the surface, then polish it with stones or fine sandpaper. Finally, I wax and buff the tool rest to ensure a silky-smooth glide for my tools. Any tools with sharp corners, like parting tools and skews, also get the easing treatment with a buffer or sandpaper to prevent damage to the rest.

The Value of a Sharp Edge

While turning tools aren’t cheap, I never confuse their cost with the value of a pleasant turning experience. In the last 15 years, I’ve had the same iron in one of my favorite spokeshaves, but I’ve replaced most of my turning tools at least once. Maintaining a sharp edge is essential for achieving consistent, high-quality results at the lathe.

As you develop your woodworking skills, don’t neglect the importance of tool maintenance. Invest the time to master sharpening techniques and keep your lathe tools in peak condition. This will pay dividends in the form of a more enjoyable, efficient, and successful turning experience.

The Importance of Continued Learning

Of course, sharpening is just one aspect of successful turning. There are many other techniques and considerations, such as lathe speed, workpiece size, and the specific details you’re trying to create. As with any craft, the journey of continuously learning and refining your skills is what makes woodworking so rewarding.

I encourage you to explore resources like woodcraftparts.net to expand your knowledge and connect with other passionate woodworkers. Whether you’re a seasoned pro or just starting your journey, there’s always more to discover in the world of woodworking.

Remember, the tools are just the beginning. It’s the skill, creativity, and dedication of the craftsman that truly brings a project to life. Keep sharpening, keep learning, and enjoy the process of mastering this wonderful art form.