Unlocking the Power of the Table Saw with Precision Sleds

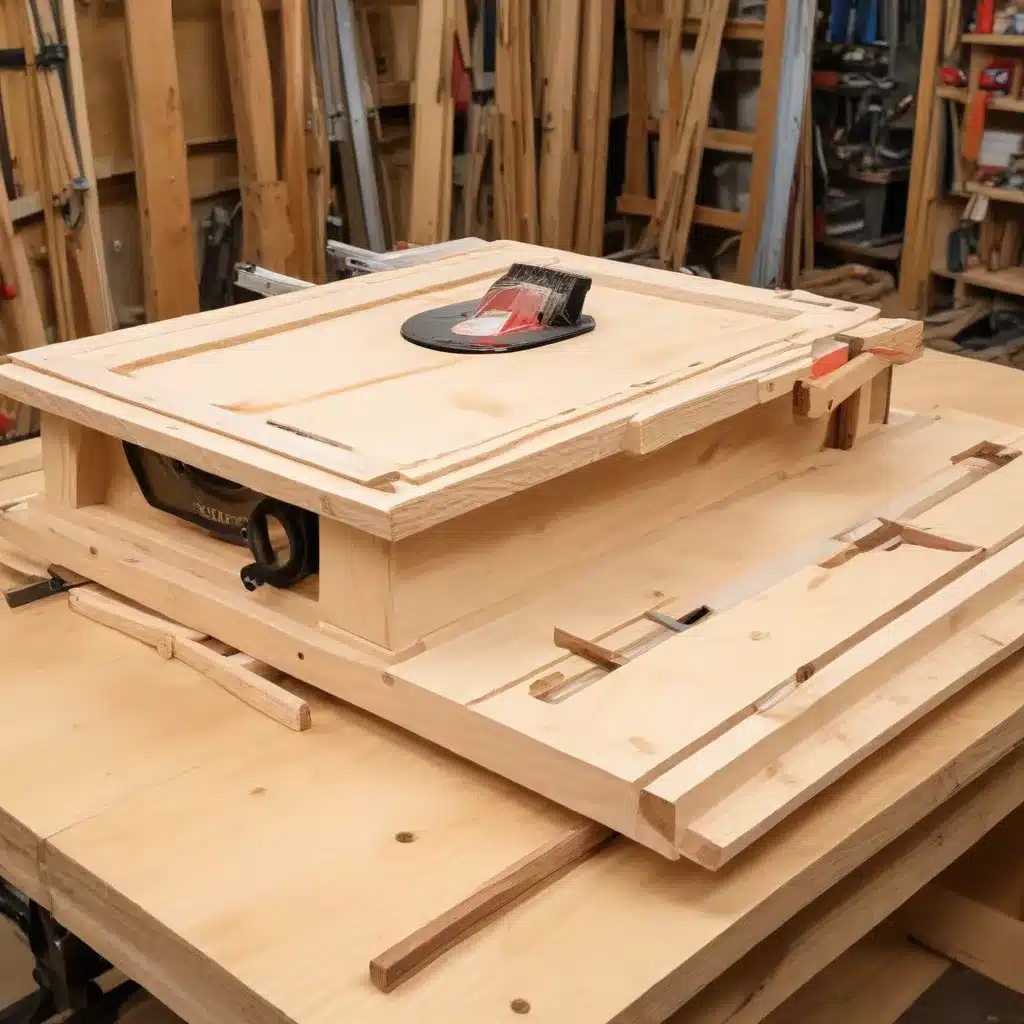

As a seasoned woodworker, I’ve come to appreciate the immense value that a well-designed table saw sled can bring to my projects. The table saw is undoubtedly a powerhouse in the workshop, but without the right accessories, it can be challenging to achieve the level of accuracy and safety that discerning woodworkers demand. That’s where the humble sled steps in, transforming your table saw into a versatile, precision-driven tool that can elevate your craftsmanship to new heights.

In this comprehensive guide, I’ll share my insights and practical tips on constructing table saw sleds that will enhance your workflow, boost your confidence, and safeguard your hands. Whether you’re a beginner looking to unlock the full potential of your table saw or an experienced artisan seeking to fine-tune your processes, these sled designs will undoubtedly become invaluable components of your woodworking arsenal.

Unlocking the Benefits of Table Saw Sleds

The table saw is a workhorse in any woodworking shop, but its true power is only realized when you pair it with the right accessories. Enter the humble table saw sled – an unassuming yet indispensable tool that can revolutionize the way you approach your projects.

One of the primary benefits of a well-crafted sled is the incredible boost in accuracy it provides. By using a sled, you can ensure your cross-cuts are perfectly square, without the risk of the workpiece drifting or binding against the blade. This level of precision is essential for projects requiring tight joints, clean edges, and seamless visual harmony.

Moreover, table saw sleds enhance safety by providing a stable, controlled platform for your cuts. Instead of wrestling with a freehand workpiece, the sled allows you to keep your hands firmly away from the blade, reducing the risk of kickback or other hazardous incidents. This peace of mind is invaluable, especially for novice woodworkers or those tackling more complex tasks.

Another key advantage of sleds is their versatility. With a few simple design tweaks, you can create specialized sleds tailored to specific needs, such as angled cuts, dados, or even large-scale panel processing. The possibilities are endless, allowing you to unlock new creative avenues and streamline your workflow.

Designing the Perfect Table Saw Sled

When it comes to table saw sled design, there is no one-size-fits-all solution. The optimal sled configuration will depend on the size and capabilities of your table saw, the types of projects you typically undertake, and your personal preferences as a woodworker. However, there are several guiding principles and fundamental design elements that can help you create a sled that truly elevates your work.

Establishing the Sled Dimensions

The starting point for any sled design is determining the appropriate dimensions. This involves carefully measuring your table saw’s surface area, as well as considering the maximum size of the workpieces you intend to process. Aim to create a sled that covers the majority of the saw’s surface, providing a stable and ample platform for your cuts.

It’s also important to consider the height of your sled’s fence. This should be tall enough to support your workpieces, but not so high that you risk cutting through the fence itself. A general guideline is to make the fence just slightly taller than the maximum depth of your table saw blade.

Choosing the Right Materials

When it comes to selecting materials for your sled, the key is to prioritize stability and precision. A sturdy, dimensionally stable base is essential, and many woodworkers opt for high-quality plywood or medium-density fiberboard (MDF) for this purpose.

For the runners, which are the crucial components that allow the sled to glide smoothly along the table saw’s miter slots, a dense hardwood like maple or oak is the preferred choice. These materials are less prone to swelling or warping, ensuring a snug, consistent fit over time.

The fence can be constructed from a similar hardwood, or you may choose to incorporate aluminum or steel components for added rigidity and longevity. Remember to carefully measure and cut these pieces to ensure a perfect 90-degree alignment with the sled’s base.

Incorporating Specialized Features

Once you’ve established the core structure of your sled, you can explore a range of specialized features to enhance its functionality. One popular addition is the inclusion of T-track or other clamping systems, which allow you to secure your workpieces more effectively and safely.

Another valuable feature is a dedicated blade guard or barrier, which can prevent accidental contact with the saw blade as it protrudes through the sled’s base. This added layer of safety can give you greater peace of mind, especially when tackling more complex cuts.

For those seeking even greater precision, the incorporation of a micro-adjustment mechanism on the sled’s fence can be a game-changer. This enables you to fine-tune the fence’s position to within fractions of a millimeter, ensuring perfectly square cuts every time.

Perfecting the Sled Alignment

One of the most critical aspects of table saw sled design is ensuring the sled’s fence is perfectly aligned with the saw blade. Even the slightest deviation can result in inaccurate, and potentially dangerous, cuts. Fortunately, there are reliable techniques and methods to help you achieve this crucial alignment.

The Five-Cut Method

A widely adopted approach is the “five-cut” method, pioneered by woodworking expert William Ng. This systematic process involves a series of carefully measured cuts that allow you to precisely adjust the sled’s fence until it is perfectly perpendicular to the blade.

The steps are as follows:

- Make an initial cut on a test workpiece.

- Flip the workpiece over and make a second cut.

- Measure the difference between the two cuts.

- Adjust the fence accordingly and repeat the process until the cuts are perfectly aligned.

- Secure the fence in place once the alignment is achieved.

This methodical approach may seem daunting at first, but with a bit of practice, it becomes a reliable and efficient way to ensure your sled is perfectly calibrated.

Leveraging Measurement Tools

In addition to the five-cut method, a variety of precision measurement tools can be invaluable in achieving sled alignment. Digital calipers, feeler gauges, and even simple combination squares can help you precisely dial in the fence’s position relative to the blade.

By taking the time to carefully measure and adjust your sled’s components, you can be confident that your cuts will be true, square, and consistent – a critical factor for projects requiring tight joinery or seamless aesthetic appeal.

Optimizing Your Sled’s Functionality

Once you’ve constructed and aligned your table saw sled, the real fun begins. By incorporating specialized features and techniques, you can unlock the full potential of your sled, transforming it into a versatile, productivity-boosting tool that will become an indispensable part of your woodworking arsenal.

Expanding the Sled’s Capabilities

One way to enhance the functionality of your sled is to explore the addition of specialized accessories or jigs. For example, incorporating T-tracks or other clamping systems can allow you to securely hold your workpieces in place, enabling more complex cuts or specialized techniques like dado joints.

Another valuable addition is a dedicated stop block or fence extension. This can help you quickly and accurately replicate identical cuts, streamlining the production of items like picture frames, shelves, or box components.

Maintaining and Refining Your Sled

Like any well-crafted tool, your table saw sled will require ongoing maintenance and refinement to ensure it continues to perform at its best. Regularly check the runners for any wear or looseness, and make adjustments as needed to maintain a smooth, snug fit in the miter slots.

It’s also a good idea to periodically clean and wax the sled’s base and fence. This will help reduce friction and ensure your workpieces glide effortlessly across the surface, further enhancing the precision and efficiency of your cuts.

Embracing the Full Potential of Your Table Saw Sled

As you’ve discovered, the humble table saw sled is a true game-changer in the world of woodworking. By investing the time and effort to design, build, and maintain a high-quality sled, you’ll unlock a whole new level of accuracy, safety, and versatility in your projects.

Whether you’re tackling intricate furniture pieces, constructing sturdy shelving, or even just cutting boards for your kitchen, a well-crafted sled will become an indispensable tool in your workshop. So, embrace the power of the sled, and let it elevate your woodworking skills to new heights.

If you’re in the market for top-quality woodworking parts and accessories to complement your sled-building efforts, be sure to check out https://woodcraftparts.net/. Their selection of high-performance tools, hardware, and materials can help you take your woodworking to the next level. Happy crafting!