As an experienced woodworker and craftsman, I’ve learned that the key to successful woodturning lies in the proper selection and use of woodturning chucks. These specialized devices are the unsung heroes that hold our workpieces securely in place, allowing us to shape, refine, and create with precision and confidence. Whether you’re a seasoned pro or just starting your woodturning journey, understanding the ins and outs of woodturning chucks can truly elevate your craft.

The Importance of Woodturning Chucks

Imagine trying to turn a beautiful bowl or a delicate pen without a reliable way to secure your workpiece. The results would likely be disastrous – the workpiece could fly off the lathe, causing damage or even posing a safety risk. This is where woodturning chucks come into play. These indispensable tools provide a secure, stable, and adjustable grip on your workpiece, allowing you to focus on the task at hand without the constant worry of your project slipping or coming loose.

But the benefits of using a high-quality woodturning chuck go beyond just preventing catastrophic failures. With a secure hold on your workpiece, you can apply greater force and pressure during the turning process, enabling you to achieve finer details, smoother finishes, and more intricate designs. This level of control and precision is crucial for both functional and artistic woodturning projects.

Anatomy of a Woodturning Chuck

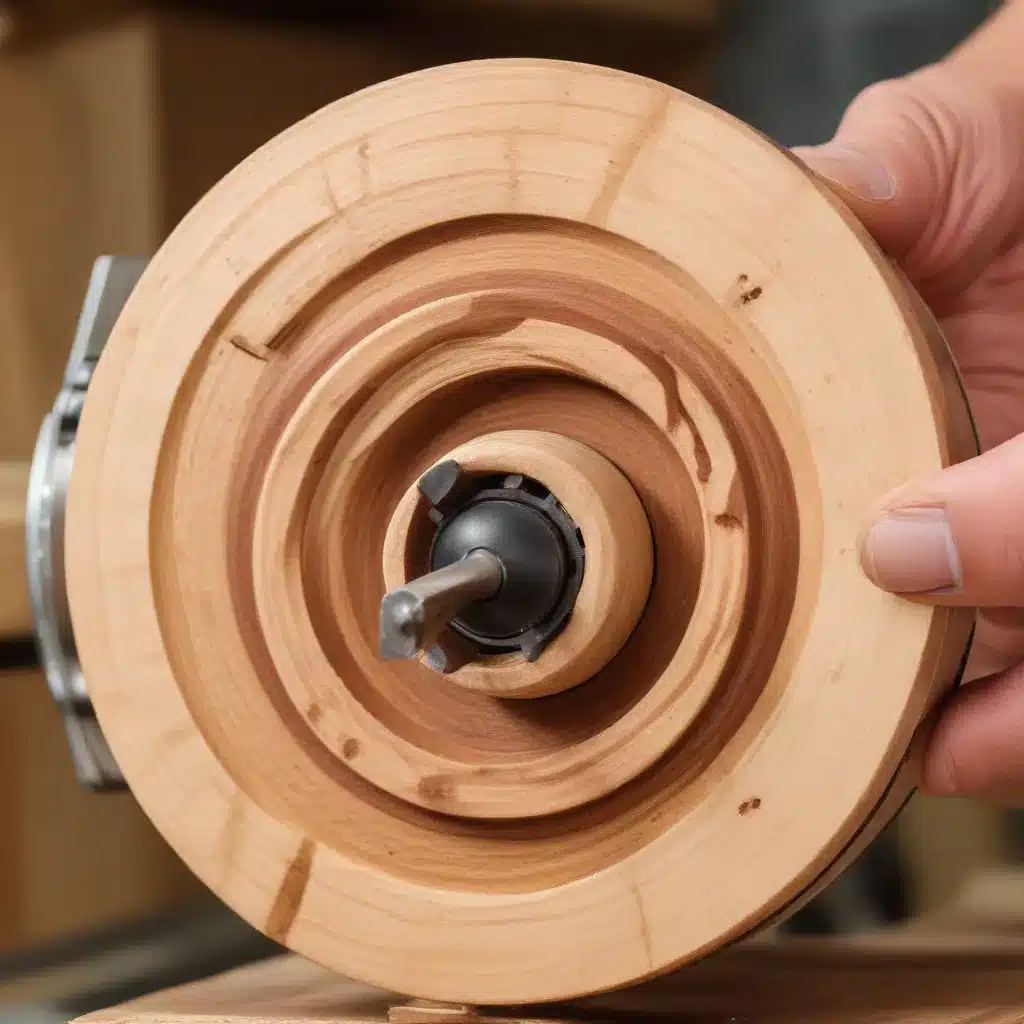

Woodturning chucks come in a variety of styles and designs, each tailored to specific project requirements and lathe specifications. At their core, these devices consist of a body, or chuck, that attaches directly to the spindle of your lathe, and a set of jaws or fingers that grip the workpiece.

The chuck body is typically made from high-quality materials like stainless steel or aluminum, ensuring durability and long-lasting performance. Many chucks also feature self-centering mechanisms, which automatically align the workpiece as you tighten the jaws, simplifying the setup process and improving overall accuracy.

The jaws or fingers are the components that actually make contact with the workpiece, providing the secure hold. These interchangeable parts come in a range of shapes and sizes, from traditional dovetail jaws to specialized scroll jaws or collets, allowing you to accommodate a wide variety of project types and materials.

Choosing the Right Woodturning Chuck

Selecting the appropriate woodturning chuck for your project is a crucial step in the process. The type of chuck you choose will depend on several factors, including the size and shape of your workpiece, the specific requirements of your turning project, and the capabilities of your lathe.

For larger turning projects, such as bowls or platters, a four-jaw self-centering chuck is often the best choice. These chucks provide a secure, well-balanced grip on the workpiece, making them ideal for handling the increased forces and stresses involved in bowl turning.

On the other hand, for smaller, more intricate work like pens or finials, a collet chuck might be the better option. Collet chucks offer a precise, concentric grip, allowing you to work with greater control and detail on these delicate projects.

Scroll chucks are another popular choice, particularly for general-purpose turning tasks. These chucks feature a set of jaws that open and close in a synchronized motion, making them versatile and easy to use for a wide range of project types.

When choosing a woodturning chuck, it’s also crucial to ensure compatibility with your lathe’s spindle size and thread configuration. Matching the chuck to your lathe’s specifications will ensure a secure, vibration-free connection, which is essential for achieving accurate and consistent results.

Mastering Woodturning Chuck Techniques

Operating a woodturning chuck effectively is a skill that comes with practice and experience. Here are some tips and techniques to help you get the most out of your chuck:

Proper Workpiece Preparation

Before mounting your workpiece in the chuck, take the time to properly prepare the surface that will make contact with the jaws. This may involve turning a tenon or recess that fits snugly into the chuck, ensuring a secure and well-centered grip.

Jaw Adjustment and Alignment

When tightening the chuck, be sure to adjust the jaws evenly and in a symmetrical pattern. This helps to distribute the clamping force evenly across the workpiece, reducing the risk of distortion or damage.

Monitoring Vibration and Balance

Keep a close eye on your workpiece during the turning process, watching for any signs of excessive vibration or imbalance. If you notice these issues, stop the lathe and investigate the cause, which may involve adjusting the chuck or re-centering the workpiece.

Tailstock Support

For longer or more slender workpieces, consider using the tailstock to provide additional support and stability. This can help to minimize deflection and vibration, allowing you to work with greater confidence and control.

Multiple Chucking Techniques

Depending on the project, you may need to employ different chucking techniques, such as using a chuck to hold the workpiece initially, then transitioning to a faceplate or vacuum chuck for the final stages of turning. Mastering these various techniques will expand your woodturning capabilities.

Maintaining and Caring for Woodturning Chucks

To ensure the long-term performance and reliability of your woodturning chucks, it’s essential to properly maintain and care for them. This includes regularly cleaning and lubricating the moving parts, checking for wear or damage, and properly storing the chuck when not in use.

When cleaning your chuck, be sure to use a gentle, non-abrasive cleaner and a soft cloth or brush. Avoid harsh chemicals or solvents, as these can damage the chuck’s components and reduce its lifespan. After cleaning, apply a light coating of a high-quality lubricant to the moving parts, such as the jaws and threads, to keep everything running smoothly.

It’s also a good idea to periodically inspect your chuck for any signs of wear or damage, such as cracked or deformed jaws, loose or damaged threads, or excessive play in the mechanism. If you notice any issues, address them promptly to prevent further damage and ensure the continued safe and reliable operation of your chuck.

By taking the time to properly maintain your woodturning chucks, you can extend their useful life, improve their performance, and have greater confidence in the security and stability of your workpieces during the turning process.

Exploring Specialty Woodturning Chucks

While the standard woodturning chucks we’ve discussed so far are essential for a wide range of projects, the world of woodturning is constantly evolving, and specialized chucks are emerging to meet the needs of more advanced or specialized turning tasks.

One such example is the vacuum chuck, which uses suction to hold the workpiece in place. These chucks are particularly useful for turning thin, delicate, or irregularly shaped items, as they minimize the risk of deformation or damage. Vacuum chucks can be especially helpful for finishing the reverse side of a bowl or platter, where traditional chucking methods may not be practical.

Another specialty chuck worth considering is the jam chuck, which is used to hold a workpiece by its inner diameter or a recessed area. Jam chucks are often employed for turning nested sets of bowls or boxes, where the workpiece needs to be supported from the inside rather than the outside.

For woodturners who work with larger, heavier projects, a faceplate or screw chuck may be the best solution. These chucks attach directly to the lathe’s spindle and provide a secure, stable platform for holding large, heavy workpieces, such as oversized bowls or platters.

As you explore the world of woodturning, don’t be afraid to experiment with different chucking techniques and specialty devices. Each one can open up new creative possibilities and help you tackle increasingly complex and ambitious projects.

The Woodcraftparts.net Advantage

At Woodcraftparts.net, we understand the importance of high-quality woodturning tools and accessories. That’s why we’ve curated a comprehensive selection of premium woodturning chucks, jaws, and related accessories to help you take your craft to new heights.

Our experienced team has hand-picked the best products from trusted brands, ensuring that you have access to the reliable, durable, and versatile tools you need to tackle any woodturning project with confidence. Whether you’re a seasoned professional or a passionate hobbyist, you’ll find everything you need to bring your woodturning dreams to life.

So why not explore our selection of woodturning chucks and accessories today? With Woodcraftparts.net as your trusted partner, you can elevate your woodturning skills, unlock new creative possibilities, and produce stunning, precision-crafted pieces that will impress and inspire.