Crafting the Perfect Cross-Cut Sled: A Beginner’s Guide

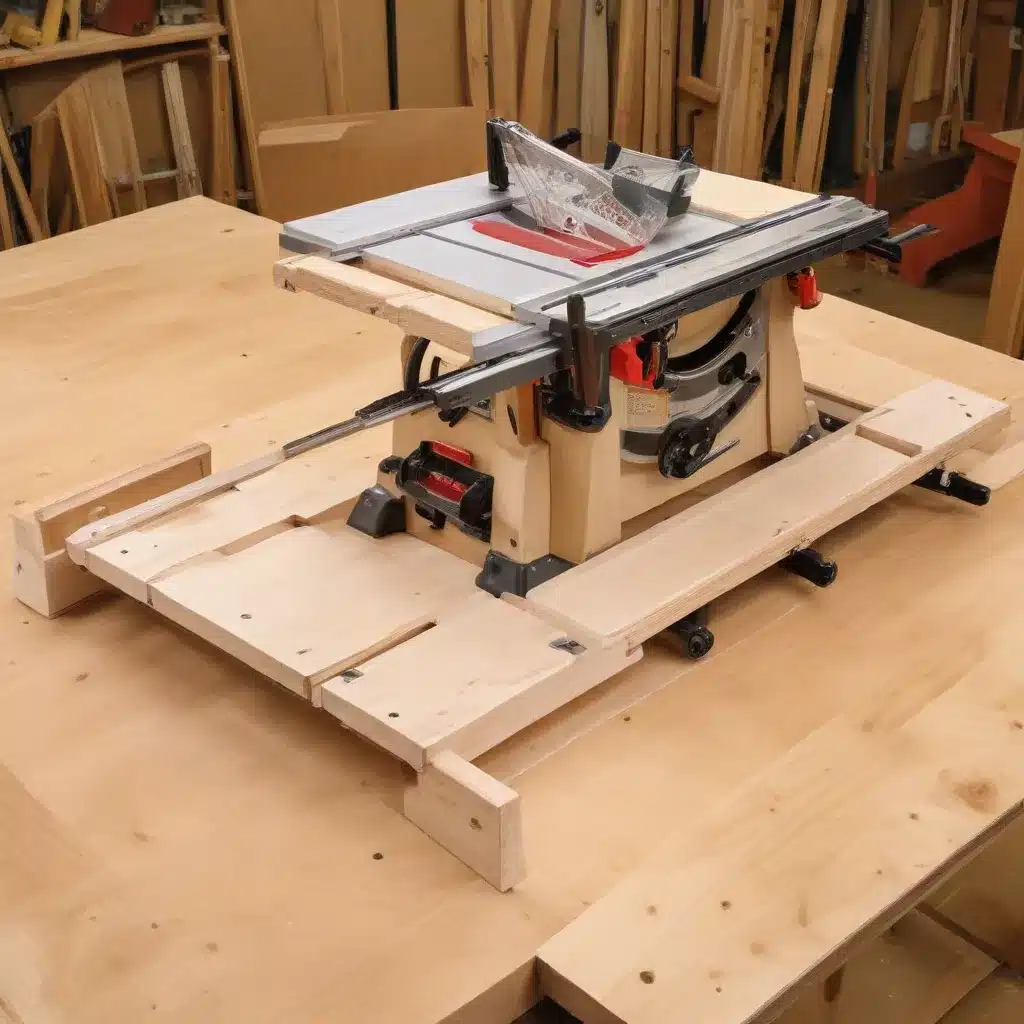

As an experienced woodworker, I’ve learned that one of the most essential tools in my workshop is the trusty table saw. Whether you’re a seasoned pro or a passionate beginner, the table saw is a workhorse that can elevate your woodworking projects to new heights. However, with great power comes great responsibility, and that’s where the humble cross-cut sled shines.

The cross-cut sled is a game-changing accessory that transforms your table saw into a precision powerhouse. By creating a stable and reliable platform for your workpieces, the sled ensures accurate, repeatable cuts time and time again. In this comprehensive guide, I’ll share my insights and techniques on designing and building a custom cross-cut sled that will revolutionize your woodworking experience.

Mastering the Art of Sled Design

The beauty of a cross-cut sled lies in its versatility. There is no one-size-fits-all design, as the specific needs of your projects and the dimensions of your table saw can dictate the optimal sled configuration. As a starting point, I recommend a general-purpose design that can handle a wide range of workpiece sizes and tasks.

The key aspects to consider when designing your sled are the size of the base, the height and length of the fences, and the precision of the runner fit within the table saw’s miter slots. The base should be large enough to support your workpieces comfortably, while the fences should be tall enough to provide stability and prevent the blade from cutting through them.

Constructing the Sled: Step-by-Step

Selecting the Base

The foundation of your sled is the base, which can be made from a variety of materials like plywood, medium-density fiberboard (MDF), or even solid wood. I personally favor a sturdy plywood base, as it provides a stable and flat surface that resists warping over time.

When choosing the dimensions, consider the size of your table saw’s surface and the largest workpieces you’ll be cutting. A base that’s approximately 24 inches deep by 30 inches wide is a good starting point, but feel free to adjust the size to suit your specific needs.

Crafting the Runners

The runners are the critical components that allow the sled to glide smoothly along the table saw’s miter slots. For the best results, use a dense hardwood like oak, maple, or even UHMW (ultra-high-molecular-weight) plastic. The runners should fit snugly within the miter slots, with just enough clearance to allow for easy movement.

To achieve the perfect fit, I recommend starting with a rough cut and then carefully trimming the runners down to size using a digital caliper or a dedicated sled-making jig. This attention to detail will ensure that your sled moves with precision, minimizing any potential inaccuracies in your cuts.

Constructing the Fences

The fences are the vertical components that guide your workpieces during the cutting process. They should be tall enough to provide stability and prevent the blade from cutting through them, typically around 5-6 inches in height. I prefer to use a high-quality hardwood for the fences, as it offers a smooth and durable surface for your workpieces to slide against.

When attaching the fences, it’s crucial to ensure that they are perfectly perpendicular to the base of the sled. The famous “5-cut” method, as demonstrated by woodworking expert William Ng, is an excellent way to achieve this level of precision. This technique involves making a series of test cuts and fine-tuning the fence alignment until you achieve a true 90-degree angle.

Incorporating Safety Features

Safety should always be a top priority when working with power tools, and the cross-cut sled is no exception. Consider adding a simple blade guard to the rear of the sled, which will help to prevent accidental contact with the spinning blade as it emerges from the back of the workpiece.

Additionally, you may want to incorporate hold-down clamps or other clamping mechanisms to secure your workpieces firmly in place during the cutting process. This extra layer of security can help to prevent kickback, a potentially dangerous situation where the workpiece is suddenly and forcefully ejected from the saw.

Mastering the 5-Cut Method for Precise Alignment

As mentioned earlier, the “5-cut” method is an invaluable technique for ensuring that your cross-cut sled is perfectly aligned. This process involves making a series of test cuts and carefully measuring the results to identify and eliminate any discrepancies.

Here’s how the 5-cut method works:

- Initial Cut: Make an initial cross-cut on a scrap piece of wood, ensuring that the fence is securely clamped in place.

- Flip and Cut: Flip the workpiece over and make a second cut on the same edge. Compare the two cuts – if they are not perfectly aligned, you’ll need to adjust the fence.

- Adjust and Re-Cut: Adjust the fence as needed, then make a third cut on the same workpiece.

- Flip and Cut Again: Flip the workpiece over and make a fourth cut on the same edge.

- Final Evaluation: Carefully measure the distance between the two cuts. If they are perfectly aligned, your sled is ready to use. If not, continue to adjust the fence until you achieve the desired 90-degree accuracy.

This meticulous process may seem time-consuming, but it’s an essential step in ensuring the long-term precision and reliability of your cross-cut sled. By taking the time to get it right, you’ll be rewarded with a tool that will serve you faithfully for years to come.

Maximizing the Versatility of Your Sled

The beauty of a well-designed cross-cut sled is its versatility. Beyond the standard cross-cutting tasks, you can adapt your sled to handle a variety of other woodworking operations, expanding the range of projects you can tackle with confidence.

Angled Cuts

By incorporating adjustable fences or additional jigs, you can use your cross-cut sled to make accurate angled cuts. This opens up a world of possibilities for creating mitered frames, compound angles, and even complex joinery.

Dado Cuts

With a few simple modifications, you can transform your cross-cut sled into a dedicated dado sled. This allows you to create precise, consistent dados and grooves across your workpieces, making it an invaluable tool for cabinet-making, shelving, and other woodworking applications.

Miter Cuts

For those times when you need to make accurate miter cuts, a cross-cut sled with adjustable fences can be a game-changer. By setting the fences to the desired angle, you can achieve perfectly mitered corners with ease, making it a breeze to create frames, boxes, and other projects that require precise miter joints.

Maintaining and Upgrading Your Sled

Like any well-crafted tool, your cross-cut sled will require some maintenance and care to keep it performing at its best. Regularly waxing or lubricating the sliding surfaces can help ensure smooth and effortless movement, while checking the fence alignment periodically can help maintain the sled’s accuracy over time.

As your woodworking skills and project needs evolve, you may also want to consider upgrading or modifying your sled. Perhaps you’ll add a more robust clamping system, incorporate a dedicated miter gauge, or even build a second sled for specialized tasks. The beauty of a custom-made cross-cut sled is that it can grow and adapt alongside your woodworking journey.

Bringing It All Together: The Sled’s Impact on Your Woodworking

The cross-cut sled is more than just a simple workshop accessory – it’s a transformative tool that can dramatically improve the quality, safety, and efficiency of your woodworking projects. By investing the time and effort to build a high-quality sled, you’ll unlock a world of new possibilities, from intricate joinery to seamless panel assembly.

As you embark on your sled-building journey, remember that the true value of this tool lies in its ability to enhance your overall woodworking experience. With a well-designed and precisely calibrated cross-cut sled, you’ll be able to tackle even the most complex projects with confidence, knowing that your cuts will be accurate, consistent, and above all, safe.

So, fellow woodworkers, let’s dive into the art of sled-making and unlock the full potential of your table saw. Together, we’ll create masterpieces that will inspire and delight for years to come. Visit woodcraftparts.net to explore a wide range of high-quality woodworking tools and accessories to elevate your craft.