As an experienced woodworker and craftsman, I’ve had the privilege of working with a wide array of tools and accessories that have truly transformed my woodworking practice. One of the most versatile and indispensable tools in my arsenal? Woodworking jigs. These unassuming yet powerful devices have the ability to elevate even the most basic projects, unlocking a world of precision, safety, and efficiency.

In this comprehensive guide, I’ll delve into the fascinating realm of woodworking jigs, exploring their diverse applications, key features, and practical tips for unlocking their full potential. Whether you’re a seasoned pro or a passionate DIY enthusiast, this article will equip you with the knowledge and inspiration to harness the power of these remarkable tools and take your woodworking to new heights.

Exploring the Versatility of Woodworking Jigs

Woodworking jigs are essentially specialized fixtures or templates that help you achieve consistent, repeatable results in your projects. These ingenious tools come in a wide variety of forms, each designed to tackle specific tasks with remarkable precision and efficiency.

From simple routing jigs that guide your router for clean, accurate cuts to more complex setups like miter saws and bandsaw sleds, the world of woodworking jigs is truly expansive. What makes these tools so valuable is their ability to elevate even the most basic of woodworking operations, transforming them into precise, reliable, and often safer processes.

One of the key advantages of using woodworking jigs is their versatility. Many jigs are designed to be compatible with a range of tools, allowing you to adapt them to your specific needs and workshop setup. This flexibility enables you to tackle a diverse array of projects, from intricate furniture making to large-scale construction, all while maintaining a high level of control and consistency.

Mastering the Art of Jig-Making

While pre-made woodworking jigs can be incredibly useful, there’s also a great deal of satisfaction and value in crafting your own custom jigs. By designing and building your own specialized fixtures, you can tailor them to the unique requirements of your projects, your tools, and your workspace.

The process of jig-making can be both challenging and rewarding. It requires a keen eye for detail, a solid understanding of woodworking principles, and a willingness to experiment and iterate. But the payoff is well worth the effort – a personalized tool that streamlines your workflow, enhances your precision, and unlocks new creative possibilities.

One of the best starting points for aspiring jig-makers is to identify recurring tasks or pain points in your woodworking routine. Maybe you struggle to achieve consistent bevel cuts on your miter saw, or you find it difficult to maintain perfect alignment when routing edge profiles. By addressing these specific needs, you can design and build a custom jig that transforms these once-challenging operations into effortless and reliable processes.

Mastering Woodworking Jig Techniques

With a vast array of woodworking jigs at your disposal, it’s important to develop a solid understanding of how to use them effectively. Each type of jig requires its own set of techniques and considerations, and mastering these can mean the difference between mediocre results and truly exceptional craftsmanship.

Let’s take a closer look at some of the key techniques and best practices for working with woodworking jigs:

Proper Jig Alignment and Adjustment

Ensuring your jig is properly aligned and adjusted is crucial for achieving precise and consistent results. This often involves carefully measuring, calibrating, and fine-tuning the various components of the jig to ensure perfect synchronization with your tools and workpieces.

For example, when using a router jig, you’ll need to meticulously position the guide bushing, adjust the fence, and align the workpiece to ensure clean, straight cuts every time. Mastering these alignment techniques takes practice, but the rewards are well worth the effort.

Clamping and Securing Workpieces

Safely securing your workpieces is essential when working with woodworking jigs. Improper clamping can lead to dangerous situations, such as the workpiece shifting or becoming dislodged during the operation. Experimenting with different clamping methods and using the appropriate clamps for the task at hand is crucial for maintaining safety and precision.

Maintaining Jig Surfaces and Components

Proper maintenance of your woodworking jigs is key to ensuring their longevity and optimal performance. This can involve regularly cleaning and lubricating the moving parts, addressing any wear or damage, and making adjustments as needed to maintain accuracy and smooth operation.

By dedicating time and attention to the care and upkeep of your jigs, you’ll be rewarded with tools that continue to deliver reliable, high-quality results for years to come.

Exploring Specialized Woodworking Jigs

While there are countless types of woodworking jigs available, some stand out for their exceptional versatility and the unique capabilities they bring to the table. Let’s dive into a few of these specialized jigs and explore how they can enhance your woodworking projects.

Versatile Trim Router Jigs

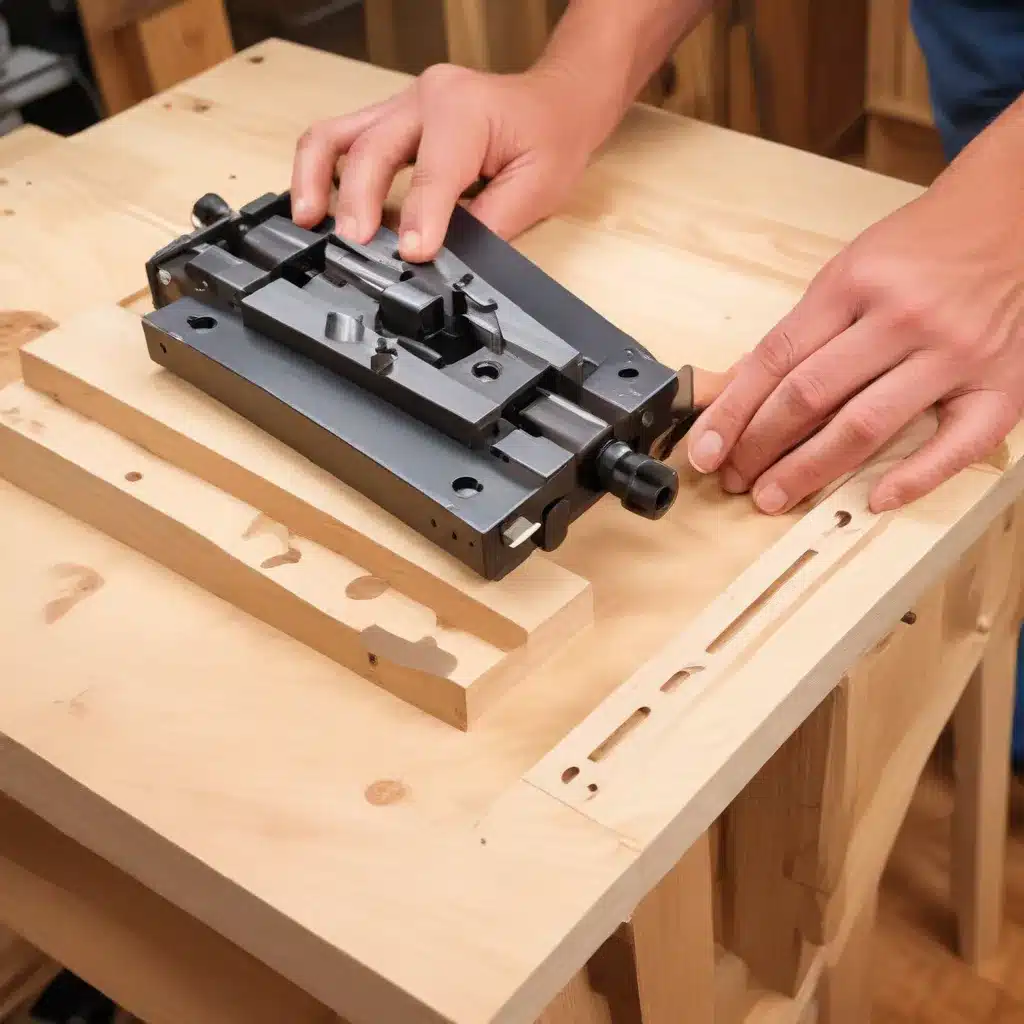

One such specialized jig that has caught my eye is the multi-functional trim router jig. This ingenious device is engineered to offer superior functionality and precision in a wide range of woodworking applications. With over eight different functions, this jig empowers users with exceptional control, facilitating precise and safe wood cutting operations.

What I find particularly impressive about this trim router jig is its versatility. It’s designed to be universally compatible, working seamlessly with a variety of popular router models. This means you can utilize this single jig across multiple tools in your workshop, streamlining your workflow and eliminating the need for multiple specialized fixtures.

From precise edge trimming and mortising to intricate dovetail and box joint creation, this trim router jig provides a remarkable level of versatility and control. Its precision CNC-machined construction and durable aviation-grade aluminum materials ensure long-lasting performance and reliability, making it a valuable asset for both professional woodworkers and DIY enthusiasts alike.

Bandsaw Sawmill Attachments

Another specialized woodworking jig that has caught my attention is the Little Ripper Bandsaw Sawmill Attachment. This innovative mini-sawmill accessory allows you to transform your humble bandsaw into a powerful milling machine, capable of transforming raw logs into usable boards and lumber right in your own workshop.

What I find particularly compelling about the Little Ripper is its ability to unlock the hidden potential of your existing bandsaw. Instead of relying on costly and space-consuming standalone sawmills, this compact and affordable attachment empowers you to mill your own lumber from firewood, downed trees, or other found materials.

The Little Ripper’s ingenious design ensures straight, accurate cuts every time, preventing common issues like blade drift that can plague less sophisticated setups. With optional attachments like circle cutters and angle cutting bases, the versatility of this jig knows no bounds, allowing you to explore a wide range of woodworking projects and techniques.

For woodworkers who value sustainability, resourcefulness, and the ability to work with unique materials, the Little Ripper Bandsaw Sawmill Attachment is a truly transformative tool that can open up a whole new world of creative possibilities.

Unlocking the Full Potential of Your Woodworking Jigs

Now that we’ve explored the diverse world of woodworking jigs and some of the specialized options available, let’s dive into practical tips and strategies for unlocking the full potential of these remarkable tools.

Experimenting and Customizing Jigs

One of the most exciting aspects of working with woodworking jigs is the opportunity to experiment and customize them to suit your unique needs. Don’t be afraid to tinker, modify, and even design your own custom jigs to tackle specific challenges or unlock new creative avenues.

By adopting a mindset of continuous improvement and innovation, you can transform your woodworking jigs into highly personalized tools that streamline your workflow, enhance your precision, and ignite your creative spark.

Integrating Jigs into your Workflow

Effective integration of woodworking jigs into your overall workflow is key to maximizing their impact. Identify the recurring tasks or pain points in your process and strategically incorporate the appropriate jigs to address them.

This might involve setting up dedicated stations or workspaces for certain jigs, ensuring they’re readily accessible and integrated seamlessly into your routine. Experimenting with different organizational strategies and storage solutions can also help you quickly and easily access the right jig for the job at hand.

Maintaining and Upgrading Jigs

As with any valuable tool, proper maintenance and upgrades are essential for ensuring the longevity and peak performance of your woodworking jigs. Regularly inspect your jigs for wear and tear, make necessary adjustments, and address any issues promptly to keep them in top condition.

Additionally, be on the lookout for innovative upgrades or accessories that can further enhance the capabilities of your existing jigs. Investing in these enhancements can elevate your woodworking projects to new heights, unlocking previously inaccessible techniques and creative avenues.

Sharing Knowledge and Collaborating

One of the most rewarding aspects of the woodworking community is the spirit of collaboration and knowledge-sharing. As you delve deeper into the world of woodworking jigs, I encourage you to connect with fellow enthusiasts, swap tips and techniques, and engage in discussions around best practices.

Whether it’s through online forums, local woodworking clubs, or simply chatting with like-minded individuals, the exchange of ideas and insights can be a powerful catalyst for your own growth and development as a woodworker. By tapping into this wealth of collective knowledge, you can continuously refine your jig-making and usage skills, and inspire others along the way.

Conclusion

In the ever-evolving landscape of woodworking, the humble yet powerful woodworking jig stands as a testament to the ingenuity and creativity of our craft. By harnessing the versatility and precision of these specialized tools, we can elevate our woodworking projects, unlock new creative frontiers, and push the boundaries of what’s possible.

As you embark on your own woodworking journey, I encourage you to embrace the world of woodworking jigs with a sense of curiosity, experimentation, and a relentless pursuit of excellence. Whether you’re a seasoned pro or a passionate DIY enthusiast, the opportunities to unlock the full potential of these remarkable tools are truly endless.

So, let’s dive in, roll up our sleeves, and explore the limitless possibilities that await us in the realm of woodworking jigs. Together, we’ll craft masterpieces, unlock new techniques, and forge a deeper connection with the timeless art of working with wood. The journey ahead is sure to be both challenging and immensely rewarding – and I can’t wait to see what we’ll create.