Woodcraft Parts Compatibility: Ensuring Seamless Integration of Components

Mastering the Art of Woodworking: Techniques, Tools, and Tips for Crafting with Confidence

As an experienced woodworker and craftsman, I’m thrilled to share insights and practical advice that will elevate your woodworking skills and projects. Woodworking is a truly rewarding pursuit, allowing us to transform raw materials into beautiful, functional creations. Whether you’re a seasoned pro or just starting your journey, there’s always more to learn and explore in this dynamic field.

Unlocking the Power of Precision Measurements

One of the cornerstones of successful woodworking is precision. When it comes to crafting with wood, the slightest miscalculation or inaccurate measurement can mean the difference between a flawless finished product and a disastrous outcome. That’s why I’m a firm believer in the importance of meticulously measuring and verifying the dimensions of every component.

At WDS Components Ltd, we take great pride in our commitment to quality control and accurate metric measurements. Our team of skilled technicians employs advanced techniques and state-of-the-art tools to ensure that every component we produce meets the strictest industry standards. From precision calipers to laser measurement devices, we leave no stone unturned in our quest for perfection.

But it’s not just about the tools – it’s also about the process. Our technicians follow rigorous protocols, meticulously verifying each dimension in millimetres to guarantee that every piece integrates seamlessly with your project. This attention to detail is what sets us apart and allows you, as a woodworker, to build with confidence.

Imagine the satisfaction of seeing your carefully crafted project come together without a hitch, thanks to the precision of the components you’re using. That’s the power of working with parts that have been meticulously measured and verified. It’s a level of quality assurance that can truly elevate your woodworking experience.

Navigating the Compatibility Conundrum

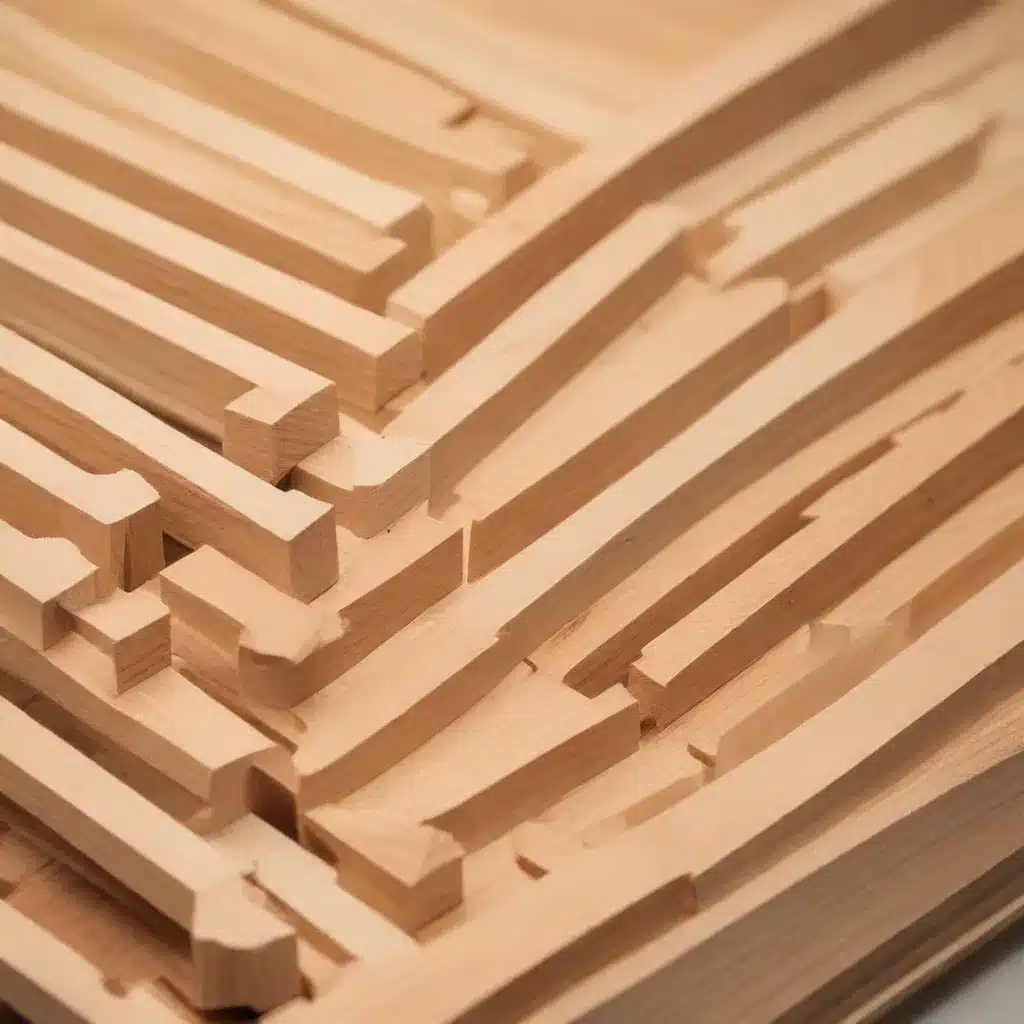

As a woodworker, you know that the success of your projects often hinges on the seamless integration of various components. Whether you’re building furniture, cabinetry, or any other woodcraft, ensuring compatibility between the different parts is crucial. This is where the WDS Components Ltd product line shines, offering a comprehensive range of solutions designed to work together harmoniously.

One of the standout features of our components is their adaptability. Our engineers have meticulously designed each piece to integrate effortlessly with a wide range of applications, allowing you to mix and match components with confidence. This level of compatibility simplifies the assembly process, reducing the risk of costly errors or time-consuming modifications.

Take, for instance, our HydraClamp miniclamp series. These versatile work positioners are designed to hold your work at any desired angle, securing it in place with a single motion of the operating lever. The beauty of these clamps lies in their ability to adapt to a variety of jigs and fitments, making them the ideal tool for the assembly of light components. Whether you’re working on intricate woodcarving projects or larger furniture pieces, the HydraClamp miniclamps can provide the precision and stability you need.

But compatibility goes beyond just the physical fit of the components. It also extends to the digital realm, where seamless integration is equally essential. That’s why we’ve invested heavily in our CAD download service, offering a vast catalogue of products in a wide range of formats suitable for all major CAD platforms. This ensures that you can effortlessly incorporate our components into your digital design workflows, streamlining the transition from virtual to physical.

By prioritizing compatibility, we empower you to focus on the creative aspects of your woodworking projects, rather than getting bogged down by technical challenges. With our precision-engineered components and digital integration capabilities, you can confidently bring your visions to life, knowing that the parts will work together flawlessly.

Embracing Eco-Friendly Woodworking Practices

In today’s increasingly conscious world, the environmental impact of our actions has become a vital consideration. As woodworkers, we have a unique opportunity to embrace eco-friendly practices that not only benefit the planet but also contribute to the longevity and sustainability of our craft.

One of the cornerstones of eco-conscious woodworking is the use of durable, long-lasting materials. At WDS Components Ltd, we are proud to offer a range of steel components that exemplify this commitment to sustainability. Steel is a highly versatile and robust material, known for its exceptional strength and corrosion resistance. By incorporating steel elements into your woodworking projects, you can ensure that your creations withstand the test of time, reducing the need for frequent replacements or repairs.

But the environmental benefits of steel extend beyond its physical properties. Steel is also 100% recyclable, meaning that at the end of a product’s lifespan, the materials can be repurposed and reused, minimizing waste and contributing to a more circular economy. This circular approach aligns perfectly with the values of the modern woodworking community, where responsible stewardship of resources is becoming increasingly important.

As you plan your next woodworking project, I encourage you to consider the integration of steel components. These durable elements can not only enhance the structural integrity and longevity of your creations but also align with your commitment to sustainable practices. By embracing eco-friendly materials and techniques, you can leave a positive impact on the environment while continuing to hone your craft.

Maintaining the Integrity of Your Woodworking Tools

No discussion of successful woodworking would be complete without addressing the importance of tool maintenance. After all, the tools we use are the extensions of our hands, and their performance can make or break the quality of our work. As an experienced woodworker, I can attest to the transformative power of well-maintained tools.

One of the key aspects of tool maintenance is ensuring that the components used in their construction are of the highest quality and precision. This is where the expertise of WDS Components Ltd comes into play. Our range of fasteners, bearings, and other hardware components are engineered to exacting standards, providing the reliability and durability that your tools demand.

Whether you’re working with hand tools or power tools, the integration of these precision-engineered components can make a significant difference in their performance and longevity. Imagine the smooth, effortless operation of a saw blade that glides through the wood, or the unwavering stability of a router that allows you to execute intricate details with confidence. These are the tangible benefits that come from investing in high-quality components that work in harmony with your tools.

But tool maintenance goes beyond just the components. It also involves regular cleaning, sharpening, and calibration to keep your tools in peak condition. By dedicating time and attention to maintaining your woodworking tools, you’re not only preserving their functionality but also extending the life of your valuable investments.

As you embark on your next project, I encourage you to take a holistic approach to tool maintenance. Pair your diligence and craftsmanship with the precision-engineered components from WDS Components Ltd, and you’ll unlock a whole new level of performance and reliability in your woodworking endeavours.

Embracing the Future: Integrating Digital Workflows

In the ever-evolving world of woodworking, we can no longer ignore the transformative power of digital technology. As we strive to enhance our efficiency, accuracy, and creativity, embracing digital workflows has become a game-changer.

One of the prime examples of this digital integration is the seamless collaboration between Fusion 360 and Cutlist Evolution. This powerful combination allows you to design your woodworking projects in Fusion 360, a leading CAD software, and then effortlessly transition to the specialized Cutlist Evolution tool for generating precise cut lists.

The beauty of this workflow lies in its simplicity and speed. By exporting your Fusion 360 model in the OBJ format, you can then import it directly into Cutlist Evolution, which will interpret the 3D data and organize it into a comprehensive, detailed cut list. This process significantly reduces the manual effort required and minimizes the potential for human error, ensuring that your cut lists are accurate and comprehensive.

But the benefits of digital integration don’t stop there. When it comes to sourcing the necessary components for your projects, the WDS Components Ltd CAD download service provides a vital link. Our extensive catalogue of products is available in a wide range of formats, ensuring seamless compatibility with the CAD software of your choice.

With just a few clicks, you can access and integrate our precision-engineered components directly into your digital design workflows. This level of integration streamlines the entire process, from conceptualization to fabrication, empowering you to focus on the creative aspects of your woodworking rather than getting bogged down by technical challenges.

As we continue to evolve and embrace new technologies, I believe that the integration of digital tools and processes will become increasingly crucial for woodworkers. By embracing these advancements, we can unlock new levels of efficiency, accuracy, and creativity, ultimately elevating our craft to new heights.

Conclusion: Crafting with Confidence

Woodworking is a dynamic and ever-evolving field, and as an experienced craftsman, I’m thrilled to share my insights and strategies with you. From the importance of precision measurements and component compatibility to the embrace of eco-friendly practices and digital workflows, each facet of the woodworking experience holds the potential to transform your creations.

By prioritizing quality, attention to detail, and a commitment to sustainable practices, you can elevate your woodworking projects and leave a lasting impression. And with the support of industry-leading solutions like those offered by WDS Components Ltd, you can confidently integrate precision-engineered components that seamlessly integrate with your vision.

As you embark on your next woodworking adventure, I encourage you to keep these principles in mind. Embrace the power of accurate measurements, the convenience of compatible components, and the benefits of eco-friendly materials. Leverage digital tools and workflows to streamline your process and unleash your creativity.

Together, let’s continue to push the boundaries of what’s possible in the world of woodworking, creating stunning, durable, and sustainable creations that inspire and delight. The future of our craft is in our hands, and with the right approach, the possibilities are endless.