The Power of Modularity in Woodworking

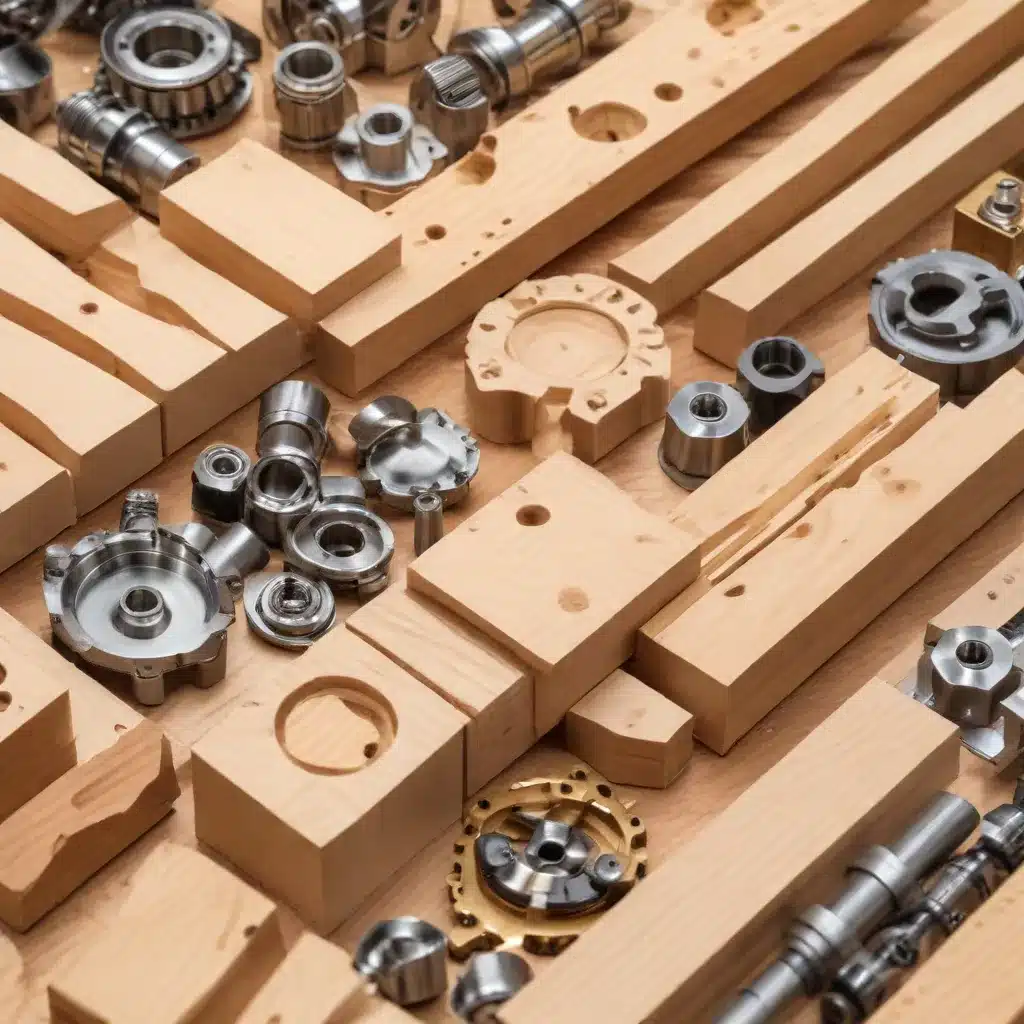

As an experienced woodworker and craftsman, I’ve come to appreciate the incredible value of modularity and interoperability when it comes to working with wood. The ability to seamlessly integrate different components and parts, whether it’s clamps, jigs, or other specialized tools, can truly elevate the woodworking experience and unlock new levels of efficiency and precision.

One of the key advantages of modular woodworking systems is the flexibility they provide. Instead of being limited to a single, rigid setup, you can mix and match various components to create the perfect configuration for your specific project. This allows you to adapt to the unique demands of each task, whether you’re tackling a complex furniture piece or a delicate woodcarving.

Take, for instance, the HydraClamp miniclamp from WDS Components. This versatile clamping tool is designed to hold your work at any desired angle, thanks to its 360-degree ball vise. With a simple motion of the operating lever, you can lock your workpiece in place, making it ideal for assembling light components or securing jigs and fixtures. The ability to reset the preload or adjust the handle position with a quick loosening of the adjustment lock screw further enhances the clamp’s adaptability.

Streamlining Your Workflow with Modular Woodcraft Solutions

But modularity in woodworking extends far beyond just clamping solutions. The envisionIT design software from Koetter Woodworking, for instance, allows you to seamlessly integrate a vast library of millwork options, including mouldings, stile and rail doors, and other architectural components, into your project. This powerful tool streamlines the design process, empowering you to visualize and specify the exact products you need to elevate your project’s aesthetic.

One of the key benefits of this modular approach is the ability to customize your woodworking solutions to suit your specific needs. Whether you require precise metric dimensions or custom-designed components, the team at WDS Components, for example, can collaborate with you to ensure the perfect fit for your application. Their commitment to quality control and meticulous measurement processes, backed by ISO 9001 certification, provides the assurance that your components will integrate flawlessly.

Embracing the Sustainability of Modular Woodworking

But the advantages of modular woodworking don’t stop at just convenience and customization. By embracing a modular approach, you can also contribute to the sustainability of your craft. Many of the components and materials used in modular woodworking systems, such as the steel used in the HydraClamp miniclamp, are highly recyclable, reducing the environmental impact of your projects.

Furthermore, the flexibility inherent in modular systems can minimize waste and optimize the use of resources. Instead of being limited to a single, rigid setup, you can adjust your configurations to minimize material consumption and maximize the efficiency of your woodworking processes.

Elevating Your Woodcraft with Innovative Technologies

But the world of modular woodworking isn’t just about the physical components – it’s also about embracing the power of innovative technologies. The 3D printing capabilities of the VX1000 industrial 3D printer from voxeljet, for instance, can open up new realms of design freedom and rapid prototyping for woodworkers.

Imagine being able to quickly and cost-effectively produce complex sand molds, investment casting patterns, or even specialized ceramic components – all with the precision and detail that modern 3D printing can deliver. By integrating these cutting-edge technologies into your woodworking arsenal, you can unlock new creative possibilities and streamline your workflow in ways that were once unimaginable.

Harnessing the Power of Interoperability

At the heart of this modular woodworking revolution is the concept of interoperability – the ability for different components and systems to work seamlessly together. By embracing interoperability, you can create a truly integrated and efficient woodworking environment, where your tools, materials, and processes all work in harmony to amplify your creativity and productivity.

Imagine a world where your 3D-printed components effortlessly integrate with your customized clamps and jigs, allowing you to tackle even the most intricate projects with confidence. Or envision a scenario where your design software seamlessly communicates with your computer-controlled machines, enabling you to translate your visions into reality with precision and speed.

Embracing the Future of Woodworking

As we look to the future of woodworking, the importance of modularity and interoperability will only continue to grow. By embracing these powerful concepts, you can future-proof your craft, ensuring that your skills and techniques remain relevant and adaptable in an ever-evolving landscape.

But the true power of modular woodworking goes beyond just the practical benefits. It’s about unlocking your creativity, empowering you to push the boundaries of what’s possible, and creating a harmonious connection between the art and the science of working with wood.

So, fellow woodworkers, I encourage you to explore the world of modular woodcraft solutions and embrace the incredible potential they offer. Whether you’re a seasoned pro or a budding enthusiast, the ability to seamlessly integrate different components and technologies can truly transform your woodworking experience, elevating your craft to new heights of precision, efficiency, and innovation.

Let’s dive into the world of woodcraft parts interoperability, and together, let’s redefine the boundaries of what’s possible in the realm of woodworking.

Unlocking the Potential of Modular Woodcraft Solutions

One of the key benefits of modular woodworking systems is the ability to customize and adapt your setup to the unique demands of each project. Rather than being limited to a one-size-fits-all approach, you can mix and match various components to create the perfect configuration for the task at hand.

Take, for instance, the HydraClamp miniclamp from WDS Components. This versatile clamping tool allows you to securely hold your workpiece at any desired angle, thanks to its 360-degree ball vise. With a simple motion of the operating lever, you can lock the workpiece in place, making it an ideal tool for assembling light components or securing jigs and fixtures.

But the real power of the HydraClamp miniclamp lies in its modularity. You can easily reset the preload or adjust the handle position by loosening the adjustment lock screw and repositioning the nut plate. This flexibility allows you to fine-tune the clamp to perfectly suit your specific needs, whether you’re working on a delicate woodcarving or a robust furniture piece.

Streamlining Your Design Process with Modular Millwork

The benefits of modularity in woodworking extend far beyond just clamping solutions. The envisionIT design software from Koetter Woodworking, for instance, provides a powerful platform for integrating a vast library of millwork options into your projects.

With envisionIT, you can browse through thousands of drawings for mouldings, stile and rail doors, and other architectural components, all while ensuring the highest quality standards. This modular approach to design streamlines your workflow, allowing you to visualize and specify the exact products you need to elevate your project’s aesthetic.

But the real magic of envisionIT lies in its ability to seamlessly integrate these modular components into your woodworking projects. By breaking down the design process into interoperable building blocks, you can create custom solutions that perfectly fit your needs, without the hassle of trying to force a one-size-fits-all approach.

Ensuring Precision and Reliability with Modular Components

As a professional woodworker, I know that precision and reliability are essential for achieving outstanding results. That’s why I’m a strong advocate for modular woodworking solutions that prioritize quality and attention to detail.

The team at WDS Components, for example, takes great pride in their commitment to delivering high-quality products with precise metric dimensions. Their meticulous measurement processes, backed by advanced tools and rigorous quality control protocols, ensure that each component they produce meets the strictest industry standards.

This attention to detail, coupled with the ability to create customized solutions, allows woodworkers like myself to have confidence in the seamless integration of our modular components. Whether you’re working with custom-designed parts or off-the-shelf solutions, the assurance of accurate metric dimensions and reliable performance is invaluable.

Embracing Sustainability through Modular Woodworking

As we navigate the evolving landscape of woodworking, it’s essential that we consider the environmental impact of our craft. Fortunately, the modular approach to woodworking provides an opportunity to embrace sustainability and reduce our ecological footprint.

Many of the components and materials used in modular woodworking systems, such as the steel utilized in the HydraClamp miniclamp, are highly recyclable. By choosing these eco-friendly options, we can minimize waste and contribute to a more sustainable future for our industry.

Moreover, the flexibility inherent in modular systems can help optimize resource utilization. Rather than being confined to a single, rigid setup, we can adjust our configurations to minimize material consumption and maximize the efficiency of our woodworking processes. This not only benefits the environment but also enhances our bottom line by reducing waste and streamlining our operations.

Integrating Cutting-Edge Technologies for Innovative Woodcraft

The world of modular woodworking isn’t just about the physical components – it’s also about embracing the power of innovative technologies to push the boundaries of what’s possible.

Take, for instance, the VX1000 industrial 3D printer from voxeljet. This cutting-edge technology allows woodworkers to quickly and cost-effectively produce complex sand molds, investment casting patterns, or even specialized ceramic components, all with unparalleled precision and detail.

By integrating these 3D printing capabilities into our modular woodworking arsenal, we can unlock new creative possibilities and streamline our workflows in ways that were once unimaginable. Imagine being able to rapidly prototype intricate design elements or fabricate custom jigs and fixtures that seamlessly integrate with your other woodworking tools and equipment.

Harnessing the Power of Interoperability

At the heart of this modular woodworking revolution is the concept of interoperability – the ability for different components and systems to work seamlessly together. By embracing interoperability, we can create a truly integrated and efficient woodworking environment, where our tools, materials, and processes all work in harmony to amplify our creativity and productivity.

Imagine a workflow where your 3D-printed components effortlessly integrate with your customized clamps and jigs, allowing you to tackle even the most complex projects with confidence. Or envision a scenario where your design software seamlessly communicates with your computer-controlled machines, enabling you to translate your visions into reality with precision and speed.

Embracing the Future of Woodworking

As we look to the future of woodworking, the importance of modularity and interoperability will only continue to grow. By embracing these powerful concepts, we can future-proof our craft, ensuring that our skills and techniques remain relevant and adaptable in an ever-evolving landscape.

But the true power of modular woodworking goes beyond just the practical benefits. It’s about unlocking our creativity, empowering us to push the boundaries of what’s possible, and creating a harmonious connection between the art and the science of working with wood.

So, fellow woodworkers, I encourage you to explore the world of modular woodcraft solutions and embrace the incredible potential they offer. Whether you’re a seasoned pro or a budding enthusiast, the ability to seamlessly integrate different components and technologies can truly transform your woodworking experience, elevating your craft to new heights of precision, efficiency, and innovation.

Let’s dive into the world of woodcraft parts interoperability, and together, let’s redefine the boundaries of what’s possible in the realm of woodworking. Visit https://woodcraftparts.net/ to discover a vast array of modular solutions and innovative technologies that can elevate your woodworking journey.