The Power of Jigs: Unleashing Precision in Woodworking

As an experienced woodworker and craftsman, I can attest to the transformative power of jigs in enhancing the accuracy and consistency of our work. In the realm of woodworking, where precision is paramount, jigs have become an indispensable tool in our arsenal. Whether you’re a seasoned pro or a passionate DIY enthusiast, understanding the art of creating and utilizing woodworking jigs can elevate your projects to new heights.

In my journey as a woodworker, I’ve learned that the difference between a masterfully crafted piece and a subpar one often lies in the attention to detail and the tools we employ. Jigs, in particular, have played a crucial role in refining my craft and ensuring that every cut, every joint, and every finished product meets the high standards I set for myself.

Mastering the Art of Measurement and Marking

Before we delve into the world of jigs, let’s first address the foundation of accurate woodworking: measurement and marking. After all, if our initial measurements and marks are off, even the most sophisticated jig won’t be able to save us from costly mistakes.

One of the most common challenges I’ve encountered is maintaining consistent and precise measurements, especially when working with fractional and decimal systems. It’s a delicate dance that requires a deep understanding of both systems and the ability to seamlessly navigate between them. Over the years, I’ve developed a few strategies that have served me well:

-

Invest in High-Quality Measuring Tools: Durable, well-designed tools can make all the difference in the world. Look for tape measures with magnetic hooks, stainless steel rulers with non-slip backing, and combination squares with built-in levels and scribes. These features not only enhance the longevity of your tools but also make the measuring process more efficient and accurate.

-

Familiarize Yourself with Increments: Knowing the common fractional and decimal increments used in woodworking is crucial. Get comfortable with the divisions of an inch, such as eighths and sixteenths, as well as the metric equivalents. This knowledge will help you make quick and confident decisions when laying out your projects.

-

Develop a Consistent Marking System: Establishing a clear and consistent system for marking your workpieces can save you countless headaches. Whether you prefer a sharp pencil, a permanent marker, or a specialized marking knife, find a method that works for you and stick to it. Clearly label your pieces to avoid confusion down the line.

-

Double-Check Your Measurements: The old adage “measure twice, cut once” is a time-honored tradition for a reason. Take the extra time to verify your measurements and alignments before making any cuts. This small but crucial step can mean the difference between a successful project and one that ends in frustration.

-

Embrace Wood Movement: As a natural material, wood is prone to expansion and contraction due to changes in moisture content. Understanding this phenomenon and accounting for wood movement in your measurements can prevent warping, cracking, and other unwanted issues.

By mastering these fundamental techniques, you’ll lay the groundwork for creating precise and consistent woodworking projects. With a keen eye for detail and a commitment to accuracy, you’ll be well on your way to producing work that truly stands out.

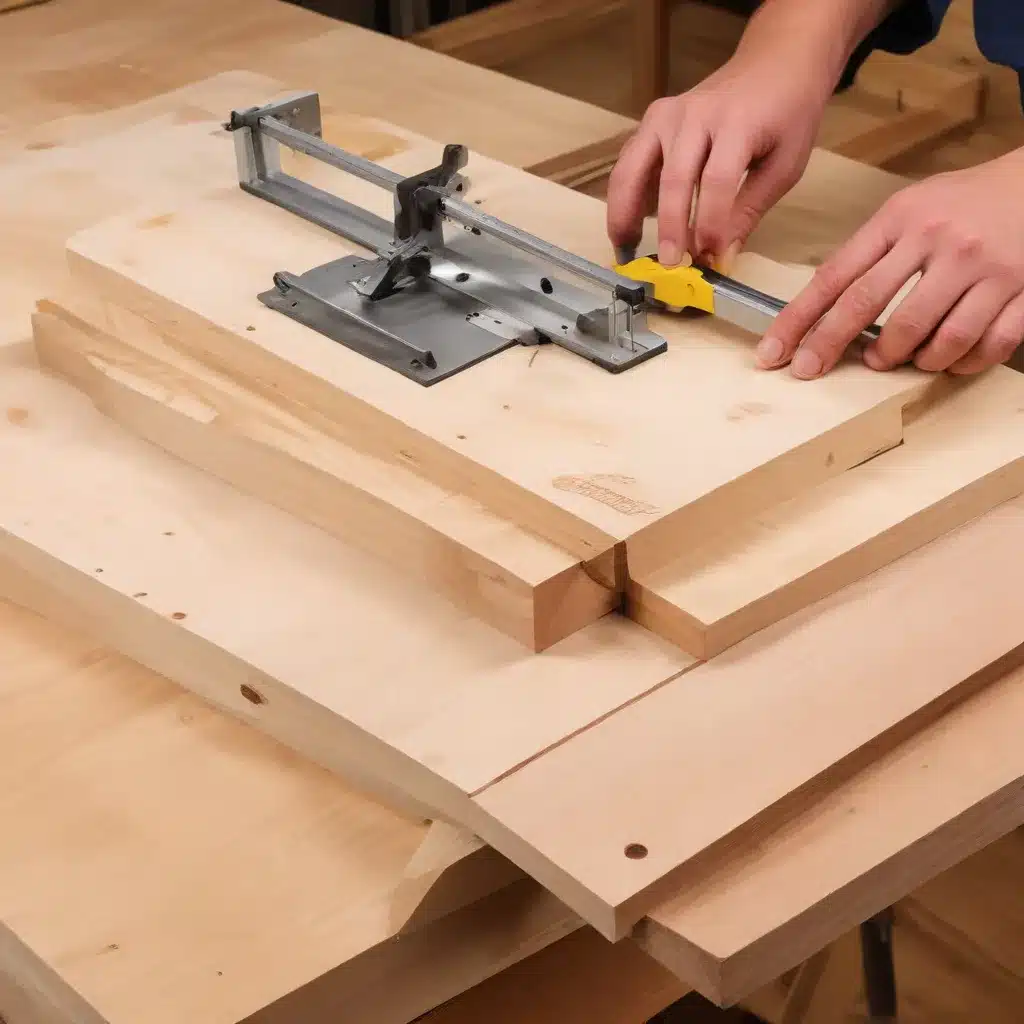

The Magic of Woodworking Jigs

Now that we’ve covered the importance of accurate measurement and marking, let’s dive into the world of woodworking jigs. These ingenious devices are designed to enhance the precision and repeatability of common woodworking tasks, from cutting to joinery and beyond.

Unlocking the Power of Jigs

Jigs are essentially specialized templates or guides that help us perform specific woodworking operations with a high degree of accuracy. They can be as simple as a basic crosscut sled or as complex as a custom-built dovetail jig. The key to their effectiveness lies in their ability to eliminate human error and provide a consistent, reliable reference point for our tools.

One of the primary benefits of using jigs is the ability to create identical parts with ease. Whether you’re building multiple cabinets, producing a set of matching chairs, or crafting complex joinery, jigs can ensure that each component is identical to the last. This level of consistency not only streamlines the assembly process but also contributes to the overall strength and aesthetics of your projects.

Designing and Building Effective Jigs

Crafting your own jigs can be a remarkably rewarding experience. It allows you to tailor the design to your specific needs and project requirements. When designing a jig, consider the following factors:

-

Purpose and Functionality: Identify the specific task you’re trying to accomplish, whether it’s cutting perfect miters, creating consistent mortise-and-tenon joints, or routing intricate patterns. This will help you determine the essential features and dimensions of your jig.

-

Durability and Stability: Jigs need to withstand the rigors of repeated use without compromising their accuracy. Opt for sturdy materials like hardwood, plywood, or metal, and reinforce critical joints and connections to ensure long-lasting performance.

-

Adjustability and Versatility: The most effective jigs are often those that can be modified or adapted to accommodate a range of project variations. Consider incorporating features like adjustable stops, guides, or clamping mechanisms to increase the versatility of your jig.

-

Safety and Ergonomics: Prioritize the safety and comfort of the user when designing your jig. Ensure that the controls and handles are easy to access and manipulate, and that the overall design minimizes the risk of injury or operator fatigue.

-

Testing and Refinement: Before using your jig for your actual project, take the time to test it on scrap material. This will allow you to make any necessary adjustments and fine-tune the design to achieve the desired level of precision.

By carefully considering these factors, you can create jigs that not only enhance the quality of your work but also streamline your woodworking process, saving you time and reducing waste.

Mastering Specific Woodworking Jigs

Now that we’ve explored the general principles of jig design and construction, let’s dive into some specific examples of how these tools can transform your woodworking projects.

Crosscut Sled: The Workhorse of the Workshop

One of the most fundamental and versatile jigs in any woodworker’s arsenal is the crosscut sled. This simple yet ingenious device allows you to make precise, straight cuts across the grain of the wood, eliminating the need for a miter saw and enhancing the safety of your cutting operations.

The key features of an effective crosscut sled include a sturdy, square fence, a smooth-running sled base, and a dedicated miter slot or T-track for securing the workpiece. By using a crosscut sled, you can ensure that your cuts are perfectly perpendicular, regardless of the size or shape of the material you’re working with.

Dovetail Jig: The Hallmark of Fine Joinery

Dovetail joints are the hallmark of fine woodworking, renowned for their strength and aesthetic appeal. Achieving consistent, well-fitted dovetails can be a challenge, but a dedicated dovetail jig can make the process much more straightforward and reliable.

A dovetail jig typically consists of a base plate with pre-drilled holes or templates that guide the placement of the workpieces. By aligning your boards within the jig and following the provided instructions, you can create intricate, interlocking dovetail joints with precision and ease.

Router Table Jigs: Unlocking Endless Possibilities

The router table is a powerful tool in the woodworker’s arsenal, but it truly shines when paired with a variety of specialized jigs. From template routing for intricate patterns to dado and rabbeting jigs for precise joinery, these accessories can unlock a world of creative possibilities.

One particularly useful router table jig is the edge-guide jig, which allows you to accurately rout along the edge of a workpiece. This can be invaluable for creating consistent, uniform profiles, such as decorative moldings or chamfered edges.

Miter Gauge Jigs: Perfecting Angled Cuts

Miter cuts are essential for creating clean, seamless joints, but they can be challenging to execute with accuracy, especially on larger workpieces. This is where miter gauge jigs come into play, providing a stable, adjustable platform for making precise angled cuts.

These jigs typically feature a miter bar that slides into the miter slot of your table saw or miter saw, along with a fence or stop that can be positioned at the desired angle. By using a miter gauge jig, you can ensure that your miter cuts are perfectly aligned, resulting in tight, gap-free joints.

Maintaining and Storing Your Woodworking Jigs

Just as we invest in the care and maintenance of our woodworking tools, it’s equally important to properly maintain and store our jigs. After all, these specialized devices are the backbone of our precision-driven craft, and keeping them in top condition is essential for consistent, high-quality results.

Calibration and Adjustments

Regularly checking the calibration and alignment of your jigs is crucial. Over time, even the most meticulously crafted jig can experience subtle shifts or misalignments, which can compromise the accuracy of your work. Make it a habit to periodically check the squareness, fence alignment, and any other critical dimensions of your jigs, and make adjustments as needed.

Cleaning and Lubrication

Keeping your jigs clean and well-lubricated is another essential maintenance task. Dust, debris, and grime can accumulate over time, affecting the smooth operation and stability of your jigs. Wipe down the surfaces and moving parts with a clean, dry cloth, and apply a thin layer of lubricant to any sliding or pivoting components.

Proper Storage and Organization

Investing in a dedicated storage system for your jigs can make a world of difference. This not only protects your valuable tools but also ensures that you can quickly locate the right jig for the job at hand. Consider using wall-mounted racks, cabinet systems, or even custom-built storage solutions to keep your jigs organized and easily accessible.

By maintaining and properly storing your woodworking jigs, you’ll ensure that they continue to perform at the highest level, year after year. This commitment to the care and upkeep of your tools will pay dividends in the form of consistently accurate and high-quality projects.

Embracing the Woodworking Revolution with Jigs

In the ever-evolving world of woodworking, the integration of jigs and specialized tools has been a game-changer. As technology continues to advance, we’ve witnessed the emergence of innovative solutions that push the boundaries of what’s possible in our craft.

One such development is the rise of Computer Numerical Control (CNC) technology, which has revolutionized the way we approach woodworking joinery. By automating the fabrication of complex wood joints, CNC machines can produce precise, repeatable cuts that enhance the structural integrity and aesthetics of our furniture pieces.

CNC wood joinery builds upon the foundations of traditional joinery techniques, such as dovetails, mortise-and-tenon joints, and tongue-and-groove connections. However, the integration of digital fabrication tools allows us to execute these intricate joints with unparalleled accuracy and efficiency, ultimately streamlining the overall woodworking process.

As we embrace these technological advancements, it’s important to maintain a balanced approach, recognizing the value of both traditional and modern techniques. By leveraging the power of jigs, whether manual or CNC-driven, we can strike a harmonious balance between time-honored craftsmanship and cutting-edge innovation.

Conclusion: Elevating Your Woodworking with Jigs

In the realm of woodworking, the use of jigs has become an indispensable tool in our pursuit of precision and consistency. By mastering the art of measurement, marking, and jig design, we can unlock new levels of accuracy and efficiency in our projects, whether we’re crafting fine furniture, creating intricate joinery, or exploring the limitless possibilities of CNC technology.

As you continue on your woodworking journey, I encourage you to experiment with different jigs, refine your techniques, and constantly seek ways to enhance your craft. Remember, the true measure of a skilled woodworker lies not only in the beauty of the final product but also in the attention to detail and the mastery of the tools at our disposal.

So, let’s embrace the power of jigs, unlock our full potential, and continue to push the boundaries of what’s possible in the world of woodworking. Together, we can create masterpieces that stand the test of time, leaving an indelible mark on the world of craftsmanship.

For more information on woodworking techniques, tools, and projects, be sure to visit https://woodcraftparts.net/. Let’s continue this journey of exploration and discovery, one jig at a time.