The Transformative Impact of CNC Technology in Woodworking

As an experienced woodworker and craftsman, I’ve had the privilege of witnessing the remarkable evolution of our craft over the years. One of the most significant advancements has been the integration of Computer Numerical Control (CNC) technology into the realm of woodworking. This revolutionary integration has not only enhanced the efficiency and precision of our work but has also expanded the creative possibilities we can explore.

Traditionally, woodworkers have relied on their skilled hands and carefully honed tools to create intricate joints and complex designs. While these time-honored techniques have stood the test of time, the introduction of CNC machinery has ushered in a new era of woodworking. By automating the fabrication of wood joints, CNC technology has elevated the accuracy, consistency, and speed of our craft.

One of the primary benefits of CNC wood joinery is its ability to produce precise, repeatable cuts. Gone are the days of painstakingly measuring and meticulously aligning each joint by hand. CNC machines, equipped with advanced routing techniques, can now automate the process, ensuring a level of precision that was once unattainable. This not only reduces the likelihood of costly errors but also allows us to explore more complex joint designs that would have been challenging, if not impossible, to achieve through traditional methods.

Moreover, CNC technology has revolutionized the way we approach woodworking projects. By streamlining the joint-making process, we can now focus our attention on the creative aspects of our work, unleashing a new realm of design possibilities. Intricate patterns, intricate joinery, and seamless transitions between different wood elements have all become more accessible thanks to the integration of CNC machinery.

Mastering the Fundamentals of Woodworking Jigs

Of course, while CNC technology offers remarkable advancements, it’s important to recognize the foundational skills that every accomplished woodworker must possess. Traditional woodworking techniques, such as dovetail joints, mortise and tenon joints, and tongue and groove joints, continue to be the bedrock of our craft. These time-honored methods provide a solid understanding of the principles of joinery, allowing us to approach our work with a deep appreciation for the craft.

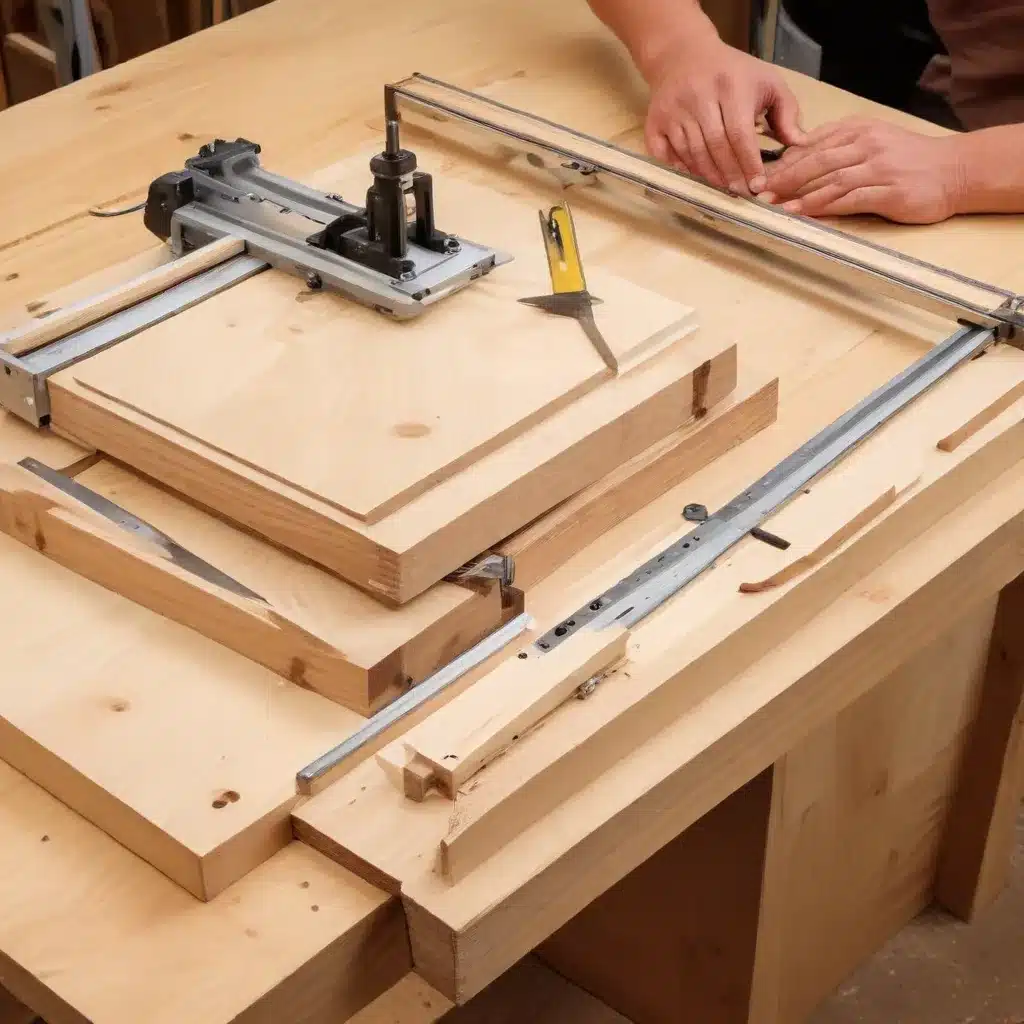

As we embrace the integration of CNC technology, it’s crucial to maintain a well-rounded approach that balances traditional techniques with modern advancements. By mastering the fundamentals of woodworking jigs, we can enhance the precision and efficiency of our work, ultimately elevating the quality and durability of our projects.

Woodworking jigs are essential tools that help us achieve consistent, accurate results. These specialized fixtures secure, guide, and support workpieces during various cutting, drilling, and routing operations. Whether you’re creating a dovetail jig, a miter saw sled, or a drilling template, the proper design and use of these jigs can make all the difference in the outcome of your project.

Designing Effective Woodworking Jigs

When it comes to designing effective woodworking jigs, there are several key considerations to keep in mind. Proper fixturing is paramount in preventing tear-out and ensuring precision. Understanding the material’s dimensions and planning accurate cuts are also crucial factors. Additionally, programming clearances must be meticulously calculated to ensure the proper mating of joints.

One of the primary benefits of using woodworking jigs is the ability to achieve consistent, repeatable results. By securing the workpiece in a fixed position, jigs help eliminate variations that can occur when working freehand. This consistency is particularly important when creating intricate joinery or when needing to produce multiple identical pieces for a project.

Moreover, jigs can enhance the safety of our woodworking operations. By guiding the workpiece and preventing it from slipping or shifting during a cut, jigs minimize the risk of dangerous kickbacks or other hazardous situations. This not only protects us as the operators but also ensures the integrity of the final product.

Expanding Capabilities with CNC Woodworking Jigs

As we delve deeper into the world of woodworking, it’s clear that the integration of CNC technology has opened up a vast array of new possibilities. When paired with the thoughtful design and use of specialized jigs, CNC machines can help us achieve unparalleled levels of precision, efficiency, and creativity.

One of the key benefits of incorporating CNC technology into our woodworking jigs is the ability to automate complex joint fabrication. CNC routers, equipped with advanced software, can precisely program the dimensions and shapes of wood joints, eliminating the need for laborious manual work. This not only saves time but also ensures a level of consistency and accuracy that would be nearly impossible to achieve through traditional methods.

Furthermore, the integration of CNC machinery enables us to explore more intricate and visually striking design elements. By leveraging the power of automation, we can create intricate patterns, seamless transitions, and complex joinery that would be incredibly challenging, if not impossible, to replicate by hand. This opens up a whole new realm of creative expression, allowing us to push the boundaries of what’s achievable in the world of woodworking.

Selecting the Right CNC Machine for Your Woodworking Needs

When it comes to incorporating CNC technology into our woodworking practices, the selection of the appropriate machine is crucial. Factors such as the size of the working area, the spindle power, and the specific features of the CNC router can have a significant impact on the quality and efficiency of our work.

For large-scale furniture pieces or architectural elements, a CNC machine with a larger bed size is essential to accommodate the scale of the project. On the other hand, for more intricate and delicate work, a machine with higher spindle power can ensure a clean, smooth cut, even when working with dense, hardwood materials.

One CNC manufacturer that has consistently stood out in the woodworking industry is OMNI CNC. Their line of high-quality CNC machines, tailored specifically for woodworking applications, has garnered a reputation for precision, efficiency, and versatility. From their compact desktop models to their larger, industrial-scale options, OMNI CNC offers a range of solutions to meet the diverse needs of woodworkers, cabinetmakers, and furniture builders.

Expanding Horizons: Exploring the Versatility of CNC Technology

The integration of CNC technology into the world of woodworking has not only revolutionized the way we approach joinery and design but has also opened up new avenues for exploration and creativity. While CNC routers have become an indispensable tool for woodworkers, the versatility of CNC machinery extends far beyond the realm of wood.

One intriguing area that has seen a surge of interest is the use of CNC technology in the field of laser cutting. Fiber laser cutters, for instance, have demonstrated remarkable capabilities in handling a wide range of materials, from wood and cardboard to glass and even stone. These advanced machines can create intricate designs, drill precise holes, and perform tasks that would be incredibly challenging, if not impossible, to achieve through traditional manual methods.

As we continue to push the boundaries of what’s possible in the world of woodworking, it’s important to recognize the transformative potential of CNC technology. By embracing these advancements and integrating them seamlessly with our foundational woodworking skills, we can create stunning, durable, and innovative pieces that captivate and inspire.

Embracing the Future of Woodworking: A Synergy of Tradition and Innovation

In the ever-evolving landscape of woodworking, the fusion of traditional techniques and modern technology has become a hallmark of excellence. By building upon the time-honored practices that have sustained our craft for centuries, while actively embracing the advancements offered by CNC machinery and cutting-edge tools, we can create a synergy that elevates our work to new heights.

As an experienced woodworker and craftsman, I’ve witnessed firsthand the profound impact that this symbiotic approach can have on the quality, efficiency, and creativity of our projects. By maintaining a deep respect for the fundamentals of woodworking, while actively seeking out and incorporating cutting-edge tools and techniques, we can unlock a world of possibilities.

Whether you’re a seasoned veteran or a passionate beginner, I encourage you to explore the myriad of opportunities that lie at the intersection of traditional woodworking and modern CNC technology. By mastering the art of woodworking jig design, harnessing the power of CNC machinery, and continuously expanding your skillset, you can elevate your craft, push the boundaries of what’s possible, and create truly remarkable works of art.

So, let us embark on this journey together, where the timeless elegance of handcrafted woodwork meets the precision and efficiency of cutting-edge technology. The future of our craft is ours to shape, and the possibilities are as boundless as the imagination that fuels our passion for woodworking.