Unleashing the Power of a Precision Table Saw Sled

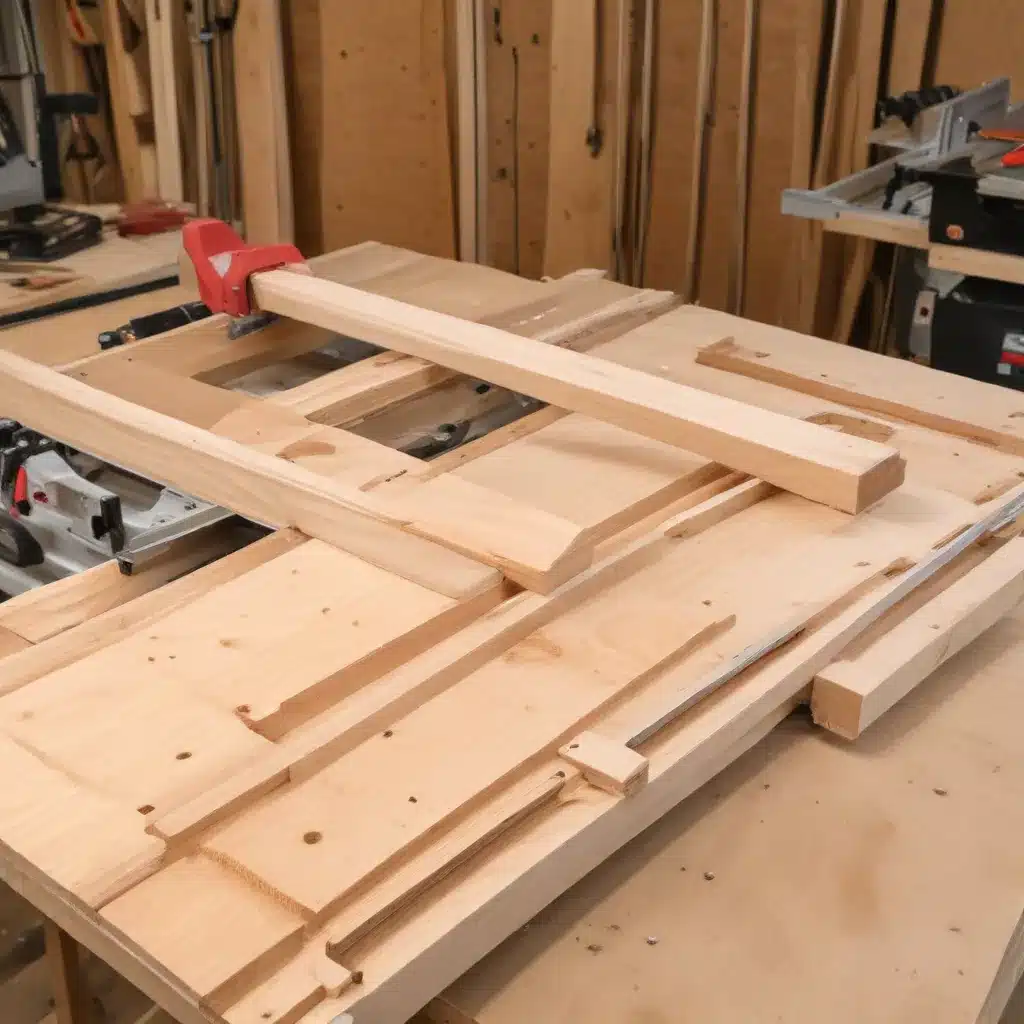

As an experienced woodworker, I’ve learned that one of the most essential tools in my arsenal is the trusty table saw. This versatile powerhouse allows me to tackle a wide range of projects, from intricate furniture-making to large-scale construction. However, the true magic happens when you pair a capable table saw with a well-designed sled. In this comprehensive guide, I’ll share my insights on crafting exceptional table saw sleds that can elevate your woodworking to new heights.

Mastering the Art of Cross-Cutting with a Sled

After acquiring a table saw, the first thing I recommend building is a cross-cut sled. This ingenious tool not only enhances the accuracy of your cuts but also significantly improves the safety of your woodworking operations. Unlike the fence on your table saw, a sled provides a stable and reliable platform for making precise cross-cuts, minimizing the risk of kickback and ensuring consistent results.

One of the key benefits of a cross-cut sled is its ability to maintain a 90-degree angle between the blade and the fence. By carefully aligning the sled’s fence, you can achieve perfectly square cuts time and time again. This is particularly important for projects that require tight tolerances, such as furniture-making or cabinetry. With a well-designed sled, you can trust that your cuts will be true and your final pieces will fit together seamlessly.

Customizing Your Sled to Suit Your Needs

While there’s no one-size-fits-all solution when it comes to table saw sleds, the beauty lies in the ability to tailor them to your specific needs. The dimensions of your sled should be determined by the size and type of projects you typically work on. For example, if you primarily handle smaller workpieces, a more compact sled may be the ideal choice. On the other hand, if you regularly tackle larger projects, a larger sled can provide the necessary support and stability.

One of the key considerations in sled design is the height of the fences. The minimum height should be just above the thickness of your workpieces, ensuring that the blade doesn’t cut through the fence during operation. This not only preserves the integrity of the sled but also enhances safety by reducing the risk of blade contact. Additionally, the width of the sled should be wide enough to accommodate your typical work, but not so large that it becomes unwieldy or takes up too much valuable workspace.

Perfecting the Runners for Smooth Gliding

The runners on your table saw sled are the unsung heroes that ensure the smooth and accurate movement of the sled across the saw’s surface. These carefully crafted components must be precisely fitted to the miter slots on your table saw, allowing the sled to glide effortlessly without any binding or wobbling.

When constructing the runners, it’s essential to use a dense, stable hardwood that is resistant to movement and warping. This helps to maintain the sled’s alignment and prevents any deviations that could compromise the accuracy of your cuts. I’ve found that materials like maple or oak work exceptionally well for this purpose, as they provide the necessary rigidity and dimensional stability.

The process of fitting the runners to the miter slots can be a delicate one, requiring a keen eye for detail and a steady hand. Using a caliper or digital gauge, I carefully measure and adjust the runners until they slide smoothly and snugly within the slots. This attention to precision is crucial, as even the slightest misalignment can have a significant impact on the accuracy of your cuts.

Achieving Perfection with the 5-Cut Method

One of the most reliable techniques for ensuring the perfect 90-degree alignment of your sled’s front fence is the renowned “5-Cut Method.” Developed by the renowned woodworking expert William Ng, this systematic approach allows you to fine-tune the fence’s position with incredible precision.

The essence of the 5-Cut Method lies in a series of carefully executed cuts that help you identify and correct any deviations from the desired 90-degree angle. By making a series of test cuts and measuring the resulting angles, you can make minute adjustments to the fence’s position until you achieve the perfect, square alignment.

This process may require a bit of patience and experimentation, but the payoff is well worth it. With a sled that is precisely aligned, you can trust that every cross-cut you make will be true and consistent, elevating the quality of your woodworking projects to new levels.

Enhancing Safety with Blade Guards and Accessories

While the primary function of a table saw sled is to improve the accuracy and precision of your cuts, it’s also a crucial tool for enhancing the overall safety of your woodworking operations. One of the essential safety features I incorporate into my sled designs is a blade guard.

This simple yet effective accessory is a small box-like structure that is attached to the rear of the sled, covering the portion of the blade that extends beyond the workpiece. By physically blocking access to the exposed blade, the guard helps to prevent accidental contact, reducing the risk of serious injury.

In addition to the blade guard, I also recommend incorporating other safety-enhancing features into your sled design. This might include the addition of stop blocks or fences to prevent the workpiece from being pulled into the blade, or the inclusion of handles or gripping surfaces to provide a secure and comfortable hold during operation.

Maintaining and Optimizing Your Sled’s Performance

Like any well-crafted tool, a table saw sled requires ongoing maintenance and attention to ensure it continues to perform at its best. I make it a habit to regularly inspect my sleds for any signs of wear or damage, such as loosened screws, warped or damaged fences, or worn runners.

When it comes to maintaining the sled’s smooth operation, I find that a light application of wax or dry lubricant on the runners and sled base can make a significant difference. This helps to reduce friction and ensures that the sled glides effortlessly across the table saw’s surface, minimizing the risk of binding or sticking.

If I notice any issues with the sled’s alignment or accuracy, I don’t hesitate to make the necessary adjustments. This might involve tweaking the fence position, replacing worn components, or even rebuilding the sled from scratch. By staying proactive and vigilant, I can ensure that my table saw sleds continue to deliver the exceptional performance and precision that I’ve come to expect.

Embracing Woodworking Creativity with Table Saw Sleds

As a dedicated woodworker, I’ve found that the table saw sled is a true enabler of creativity and innovation. By having a reliable, accurate, and safe tool at my disposal, I’m able to explore a wide range of woodworking projects with confidence, pushing the boundaries of what’s possible.

Whether I’m crafting intricate furniture pieces, constructing large-scale architectural elements, or experimenting with unique joinery techniques, the table saw sled is a constant companion that helps me achieve my visions with precision and efficiency. By continuously refining and improving my sled designs, I’m able to tackle increasingly complex challenges, secure in the knowledge that my cuts will be true and my results will be consistently exceptional.

If you’re a fellow woodworking enthusiast, I encourage you to embrace the power of the table saw sled and let it elevate your craft to new heights. With a little creativity, a keen eye for detail, and a commitment to safety, you too can harness the transformative potential of this essential woodworking tool. The journey of mastering the table saw sled is one of endless discovery, and I’m excited to see what you’ll create along the way.

Remember, at https://woodcraftparts.net/, we’re dedicated to providing the highest-quality woodworking parts and accessories to support your creative endeavors. Whether you’re in need of custom-made components for your table saw sled or seeking inspiration for your next project, our team is here to help you succeed. Happy woodworking!